Introduction to Round Steel

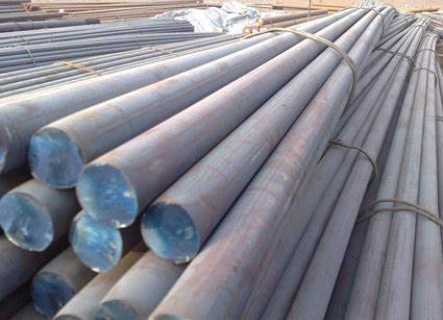

Round steel, also known as round bar or rod steel, is a long, cylindrical metal product with a circular cross-section. It is one of the most widely used forms of steel in industrial and construction applications due to its versatility, strength, and ease of fabrication. Typically manufactured through processes like hot rolling, cold drawing, or forging, round steel is available in various grades, diameters, and surface finishes to meet diverse engineering requirements. This material plays a critical role in sectors ranging from construction and machinery to automotive and energy.

Round steel is produced using three primary methods:

Hot Rolling: Heated steel billets are passed through rollers to shape them into round bars. This method yields cost-effective, large-diameter bars but with a slightly rougher surface.

Cold Drawing: Hot-rolled bars are further processed at room temperature to achieve precise dimensions, smoother surfaces, and enhanced mechanical properties.

Forging: High-pressure shaping improves grain structure, resulting in superior strength and durability, often used for critical components.

CREDIT

Round steel exhibits high tensile strength, ductility, and machinability. Its uniform shape ensures consistent performance in load-bearing applications. Surface treatments (e.g., galvanizing, polishing) or heat treatments (quenching, tempering) can further tailor its properties.

Construction: Used as reinforcement bars (though distinct from ribbed rebar), bolts, and structural supports.

Machinery: Shafts, gears, and hydraulic components benefit from its precision and durability.

Automotive: Axles, suspension parts, and engine components rely on its strength-to-weight ratio.

Energy: Drill rods, turbine shafts, and pipeline systems in oil, gas, and renewable energy sectors.

Daily Use: Furniture, kitchenware, and decorative elements leverage its aesthetic and functional qualities.

Adaptability: Easily cut, welded, or machined into complex shapes.

Cost-Efficiency: Hot-rolled variants offer economical solutions for bulk projects.

Corrosion Resistance: Stainless steel grades extend service life in corrosive environments.

Round steel adheres to international standards (e.g., ASTM, DIN, JIS) and is available in diameters from 5mm to 300mm. Custom lengths or surface coatings (e.g., black oxide) can be specified for specialized needs.

As a foundational material in modern industry, round steel combines mechanical excellence with broad applicability. Its ongoing evolution in metallurgy and processing techniques ensures it remains indispensable for both everyday objects and cutting-edge technologies. Engineers and designers continue to rely on its reliability to build safer, more efficient structures and machines worldwide.