INTRODUCTION

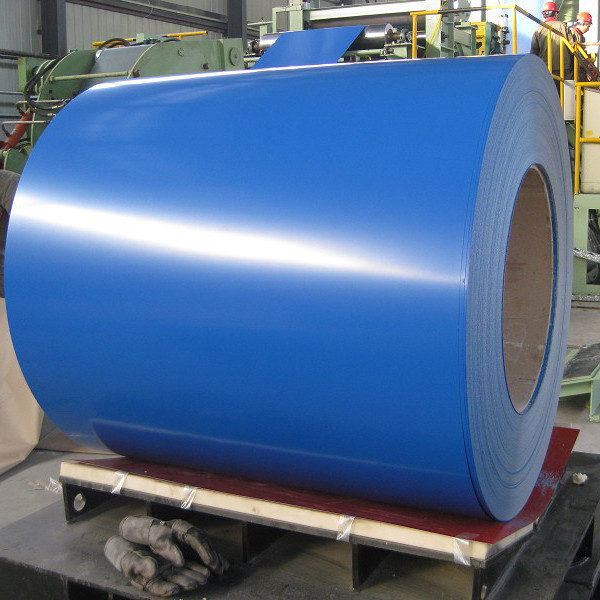

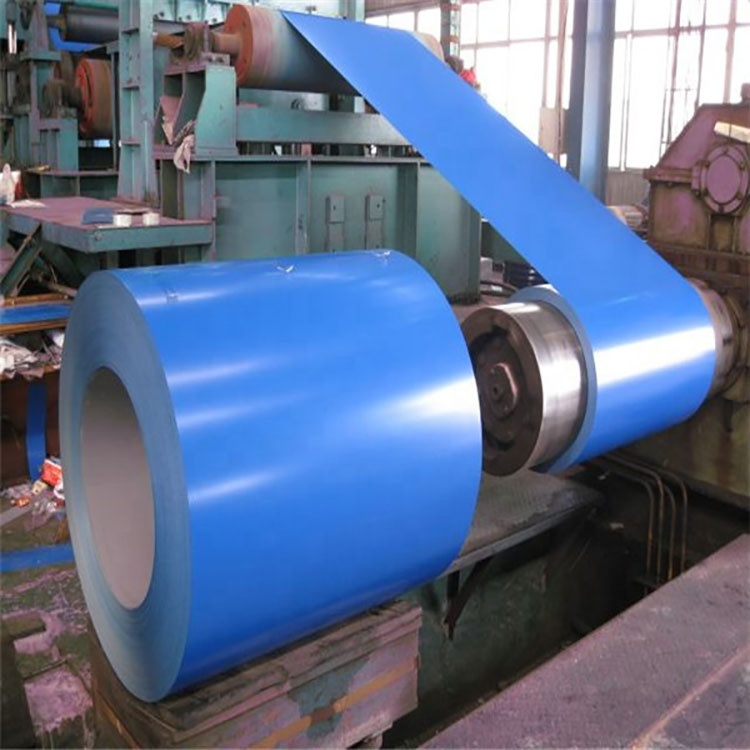

Pre-painted coil, also known as color-coated steel coil, is manufactured from hot-dip galvanized steel, hot-dip aluminum-zinc steel, or electro-galvanized steel sheets. These substrates undergo surface pretreatment before being coated with one or multiple layers of organic paint, followed by baking and curing. The resulting product is a durable, aesthetically appealing steel coil available in various colors, commonly referred to as Pre-Painted Galvanized Iron (PPGI) or color-coated steel coil.

CREDIT

APPLICATION, SPECIFICATION AND ADVANTAGE

PPGI is widely used in construction, furniture manufacturing, and metal fabrication due to its versatility and superior performance.

Key Specifications:

Width: 600mm – 2000mm

Length: Customizable based on user requirements

Thickness: 1.2mm – 25.4mm

Coating Types: Polyester, polyurethane, PVDF, and other specialized finishes

Advantages Over Traditional Galvanized Steel:

Enhanced corrosion resistance

Superior heat resistance and reflectivity

Excellent formability and paint adhesion

Wide range of colors and finishes for aesthetic applications

TREND AND PROSPECT

The primary demand for PPGI comes from the construction sector, driven by rapid urbanization, population growth, and increasing environmental concerns. Its applications in building facades, roofing, and fencing have made it a key material in modern architectural design.

Market Growth Projections:

Global Market: Expected to reach $14.58 billion by 2026, growing at a CAGR of 5.3%

China Market: Forecasted to exceed ¥200 billion by 2023, reflecting strong domestic demand

INSPECTION STANDARD

To ensure high performance and durability, PPGI undergoes rigorous quality checks, including:

Surface Inspection – No bubbles, cracks, or scratches; smooth and uniform finish

Dimensional Accuracy – Compliance with specified thickness, width, and length tolerances

Mechanical Testing – Tensile strength, impact resistance, and hardness verification

Chemical Composition Analysis – Ensures material conformity to industry standards

Non-Destructive Testing (NDT) – Ultrasonic and X-ray inspections to detect internal defects

Corrosion Resistance Testing – Salt spray and environmental exposure tests

Packaging & Labeling – Proper identification with product details (name, specifications, manufacturer)