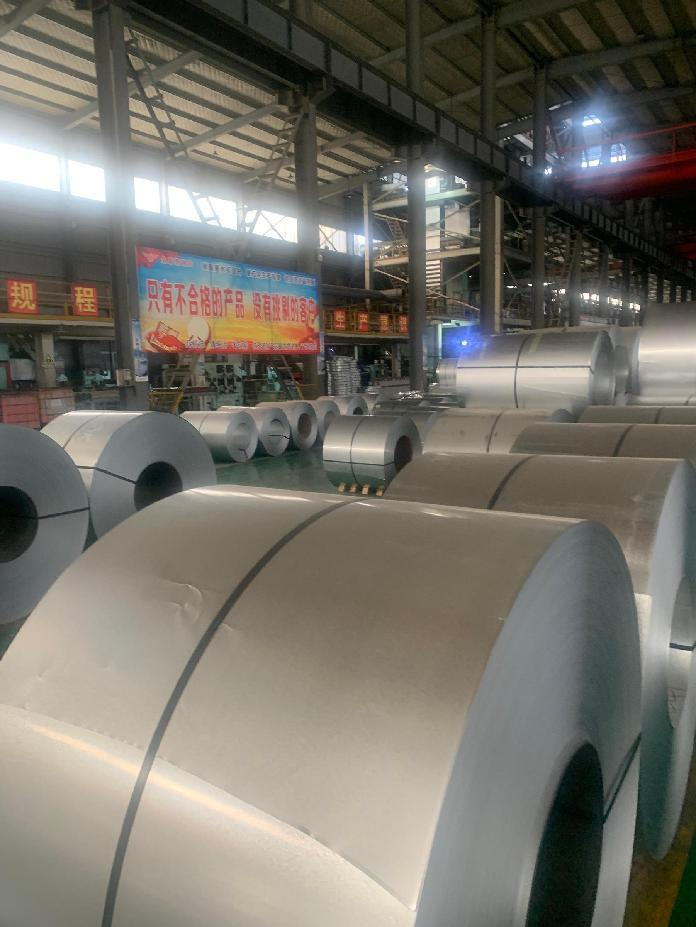

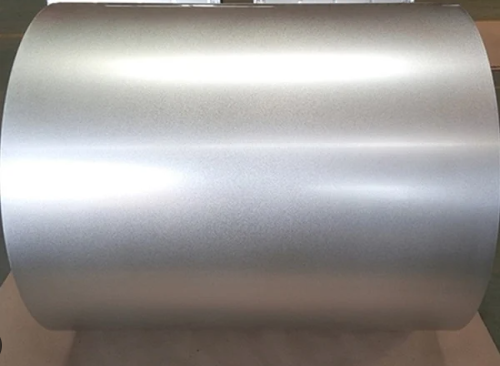

Galvalume steel coil - GL

Standard | JIS G3321, BSEN 10346, AS 1397, ASTM A792-A972M |

Tensile strength | ≥ 270 (N/mm2) |

Base metal thickness | 0,15 - 1,5 (mm) |

Width | 750 - 1250 (mm) |

Coil ID | 508 (±10), 610 (±10) (mm) |

Coil OD | 900 ≤ Φ ≤ 2000 (mm) |

Coil weight | ≤ 25 ton |

Coating mass | AZ040 - AZ200 |

T-bend | ≤2T |

Application | Roofing, partition, bare board, Rolling door, bare to paint, gutter. Other building construction uses: batten, C - truss, frame,... |

Galvalume steel coil is a type of steel sheet that has been coated with an alloy consisting primarily of aluminum and zinc. This unique coating provides a high degree of corrosion resistance, making it an ideal material for a wide range of applications, especially in environments that are prone to rust and corrosion. The typical composition of Galvalume coating is 55% aluminum, 43.4% zinc, and 1.6% silicon, which together create a robust barrier against the elements.

The production of Galvalume steel involves a sophisticated process that ensures the material’s superior durability and corrosion resistance. Here’s a detailed breakdown of each step in the manufacturing process:

Before the coating process begins, the cold-rolled steel sheets undergo thorough cleaning to remove any impurities, such as oil, dirt, and mill scale. This step is crucial to ensure that the coating adheres properly to the steel surface. The cleaning process typically involves alkaline cleaning, rinsing, and acid pickling.

After cleaning, the steel sheets are heated in an annealing furnace. This step, known as annealing, alters the microstructure of the steel to make it more ductile and workable. During annealing, the steel is heated to a specific temperature and then slowly cooled, which relieves internal stresses and improves the steel’s mechanical properties.

The core of the Galvalume steel production process is the hot-dip coating. In this step, the cleaned and annealed steel sheets are passed through a molten bath containing the aluminum-zinc alloy. The composition of the bath is typically 55% aluminum, 43.4% zinc and 1.6% silicon. As the steel sheets exit the bath, they carry a layer of the molten alloy, which solidifies on cooling.

Once the coating has solidified, the Galvalume steel sheets may undergo additional treatments to enhance their properties such as chromating, oiling,…

Throughout the production process, rigorous quality control measures are implemented to ensure that the Galvalume steel meets industry standards. These measures include coating thickness measurement, mechanical testing, corrosion testing,…

Galvalume steel coils are used in a variety of applications due to their exceptional durability and corrosion resistance. Some of the most common uses include:

Roofing and Siding: Ideal for residential, commercial, and industrial buildings due to its long-lasting protection against weather.

Automotive Industry: Used in the manufacturing of car parts to enhance durability and resistance to rust.

Appliances: Commonly found in household appliances such as refrigerators and washing machines.

Agricultural Equipment: Provides a durable and rust-resistant material for farming tools and structures

CREDIT

Galvalume steel coils offer numerous benefits that make them a preferred choice for various industries:

One of the primary benefits of Galvalume steel coils is its outstanding corrosion resistance. The aluminum-zinc coating provides a robust barrier against rust and corrosion, significantly extending the lifespan of the steel. This makes it ideal for applications in harsh environments where exposure to moisture and chemicals is common.

Galvalume steel coil has excellent heat reflectivity due to the aluminum content in its coating. This property makes it an energy-efficient material, particularly useful in building applications.

Galvalume steel has a smooth, shiny appearance that is aesthetically pleasing. This makes it a popular choice for architectural applications where both durability and appearance are important.

While the initial cost of Galvalume steel may be higher than some other materials, its long-term benefits make it a cost-effective solution. The superior corrosion resistance reduces the need for frequent maintenance and repairs, saving costs over the lifespan of the product.

Galvalume steel coil is highly versatile, suitable for a wide range of applications across different industries. It can be used in a variety of applications, from roofing and siding to automotive and household appliances, making it a versatile choice for manufacturers and builders.

Galvalume steel is an environmentally friendly material that contributes to sustainability in several ways. One of its key environmental benefits is its recyclability. Galvalume steel is fully recyclable, reducing waste and conserving natural resources. It can be reprocessed and reused in the production of new steel products.

The combination of aluminum and zinc in the coating provides Galvalume steel with exceptional strength and durability. This ensures the material maintains its structural integrity even under extreme weather conditions, making it suitable for use in areas prone to severe weather.

Despite its strength and durability, Galvalume steel coil is relatively lightweight compared to other materials. This makes it easier to handle and install, reducing labor costs and installation time. The lightweight nature of Galvalume steel also makes it more cost-effective to transport, further reducing overall project costs.