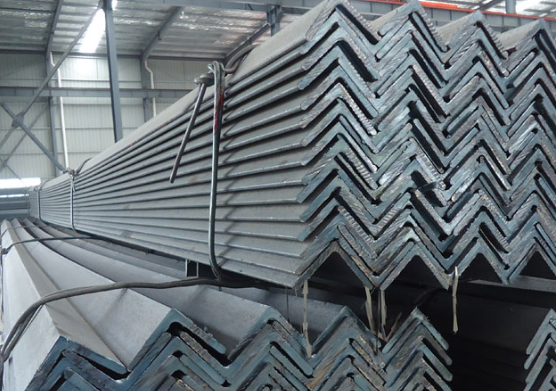

Hot-dip galvanized angle steel is an angle steel product processed by the hot-dip galvanizing method. It has a uniform galvanized layer that effectively prevents the angle steel from corroding and increases its service life. This kind of angle steel is usually made from carbon steel angle steel and then undergoes hot-dip galvanizing.

CREDIT

The surface of each finished product will go through special anti-corrosion treatment.

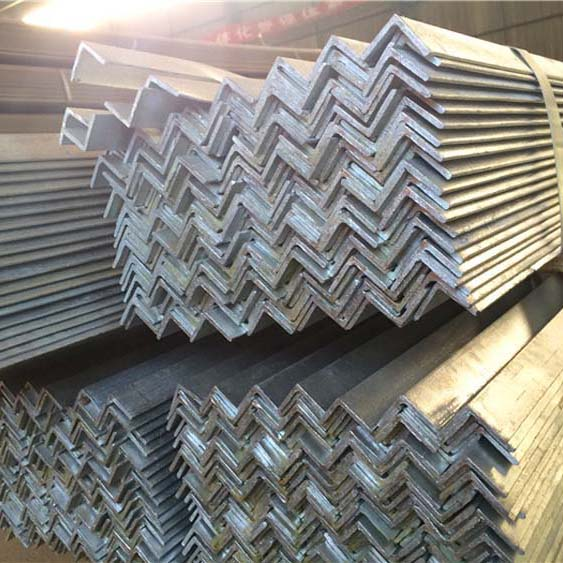

Common Specifications of Hot-dip Galvanized Angle Steel Hot-dip galvanized angle steel comes in a variety of specifications. According to different application needs, appropriate sizes can be chosen. For example, the side lengths of hot-dip galvanized angle steel can range from 20 mm x 20 mm to 200 mm x 200 mm, with thicknesses varying from 3 mm to 20 mm, and lengths typically available from 3 meters to 12 meters.

CREDIT

Hot-dip Galvanized Angle Steel Product Applications Due to its strong corrosion resistance, high strength, and good stability, hot-dip galvanized angle steel is widely applied in many fields. It is commonly used in construction projects for building frameworks, in industrial plants for equipment support structures, in power transmission towers, and in bridge construction for load-bearing components.

Advantages of Hot-dip Galvanized Angle Steel Products The significant advantages of hot-dip galvanized angle steel are its excellent corrosion resistance and long-lasting durability. It can maintain its structural integrity in various adverse environmental conditions, reducing maintenance efforts and replacement costs. Moreover, it has good mechanical properties, meeting the requirements of different engineering structures.

Hot-dip Galvanized Angle Steel product quality Inspection Process The quality inspection of hot-dip galvanized angle steel involves multiple steps to ensure product quality and performance. Firstly, the raw material angle steel is rigorously inspected to ensure it meets the production requirements. After hot-dip galvanizing, a series of tests are conducted, including zinc layer thickness measurement, surface defect inspection, dimensional accuracy verification, and mechanical property testing such as yield strength and tensile strength tests. Finally, the qualified products are carefully packaged and stored for dispatch.