Keywords: Seamless Pipe, Manufacturing, Quality

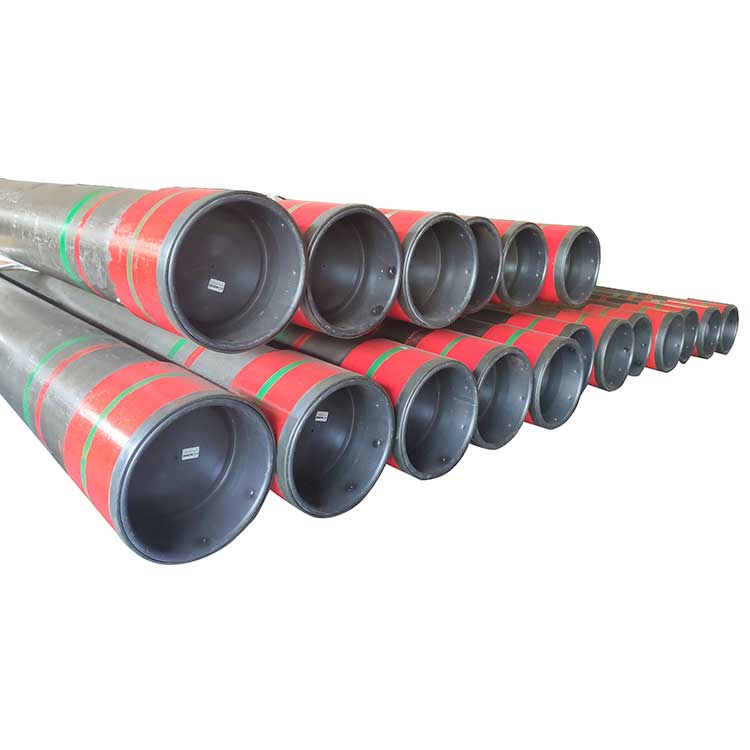

Seamless pipes are a vital component in numerous industries due to their strength, reliability, and versatile applications. Unlike welded pipes, seamless pipes are formed from a solid billet of metal, which is then heated and extruded into a tube shape without any seams or joints. This manufacturing process results in pipes that are inherently stronger and more resistant to pressure and mechanical stresses. The absence of seams makes these pipes ideal for use in high-pressure applications, such as in oil and gas pipelines, boilers, and chemical processing industries. As seamless pipes are produced through continuous extrusion, they exhibit uniform strength and quality throughout their length, ensuring better performance and safety standards.

CREDIT

Keywords: Applications, Industries, Durability

Seamless pipes are used across various industries, including oil and gas, automotive, aerospace, and construction. In the oil and gas industry, seamless pipes are essential for the transportation of natural gas, crude oil, and refined products due to their ability to withstand high internal pressures. Their durability and resistance to corrosion also make them an ideal choice for pipelines located in harsh environments, such as deep-sea installations or areas with extreme temperatures. In automotive manufacturing, seamless pipes are often used in engine components and exhaust systems, where they need to endure high thermal and mechanical stress. The aerospace industry uses seamless pipes for lightweight, high-strength components that can withstand the high stresses and pressures of flight.

Keywords: Production, Standardization, Maintenance

The production of seamless pipes involves a range of techniques, such as extrusion, rotary piercing, and elongation. The pipes are subjected to strict quality control measures to ensure they meet international standards, including ASTM, DIN, and API specifications. These standards cover factors like wall thickness, outer diameter, tensile strength, and corrosion resistance, ensuring that each pipe performs optimally in its intended application. Despite their superior strength and durability, seamless pipes require regular maintenance and inspection, especially when used in critical industries like oil and gas. Over time, factors such as corrosion, fatigue, and external damage can compromise their integrity, making routine inspections necessary to prevent failures and ensure safety.

CREDIT