(I)Define

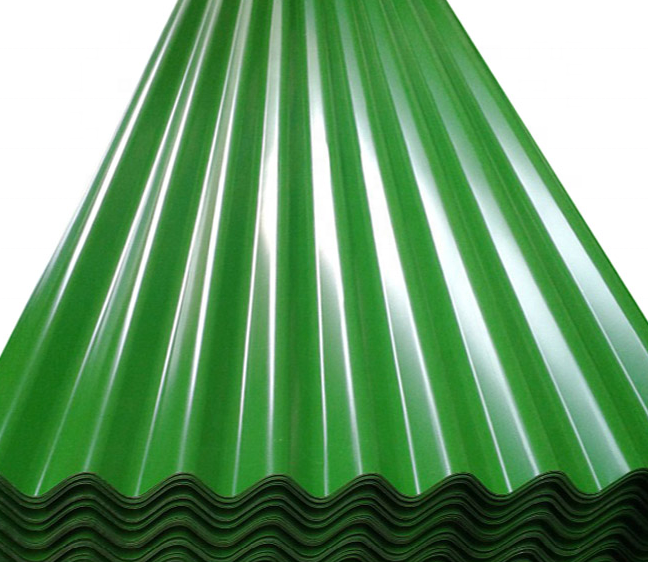

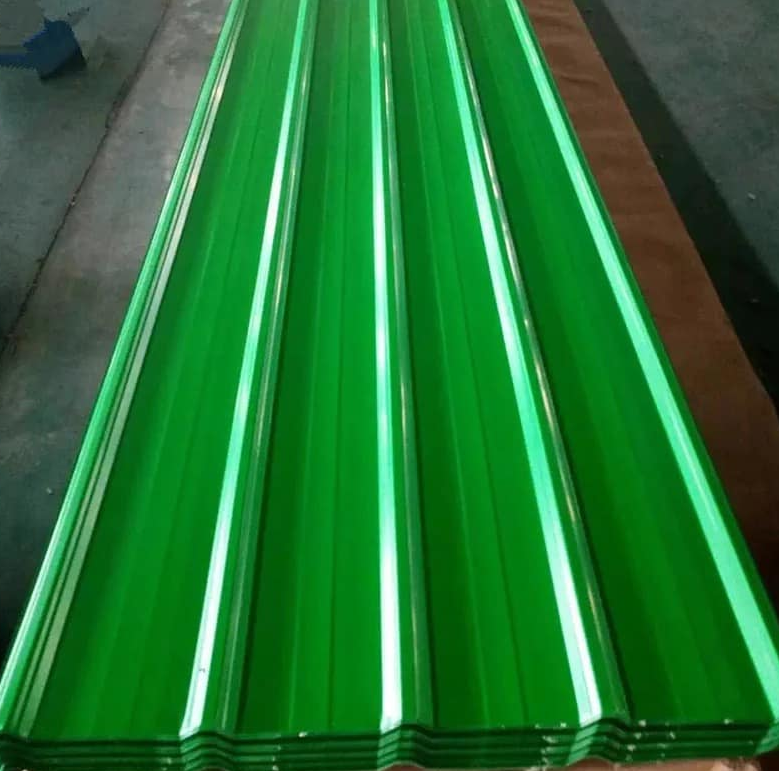

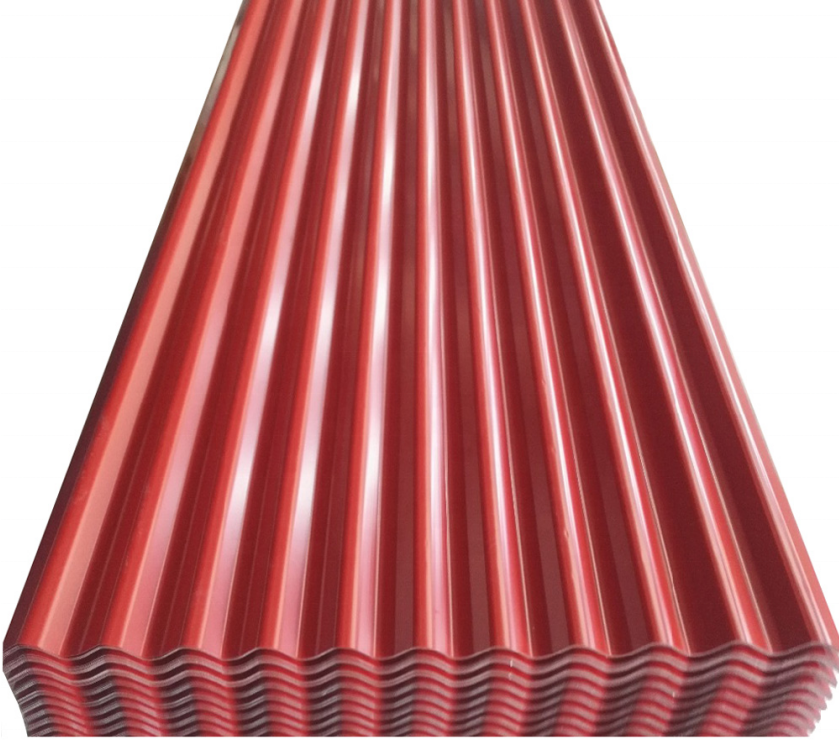

On the continuous unit, cold-rolled strip steel and galvanized strip steel (electro-galvanized and hot-dip galvanized) are used as the substrate. After surface pre-treatment (degreasing and chemical treatment), one or more layers of liquid are applied by roller coating. Coating, the plate obtained after baking and cooling is the coated steel plate. Since the coating can have various colors, it is customary to call coated steel plates color-coated steel plates. And because the coating is carried out before the steel plate is formed and processed, it is called pre-coated steel plate abroad.

(II)process flow

Color-coated steel plates are made by using cold-rolled steel plates and galvanized steel plates as base plates. They undergo surface pretreatment (degreasing, cleaning, chemical conversion treatment), are coated with paint in a continuous method (roller coating method), and are baked and cooled. finished product.

The main production processes of the common two-coating and two-baking continuous color coating unit are: uncoiling → pretreatment → coating → baking → post-processing → coiling.

CREDIT

(III)Application

Coated steel plates are lightweight, beautiful, have good anti-corrosion properties, and can be directly processed. They provide a new type of raw material for the construction industry, shipbuilding industry, vehicle manufacturing industry, furniture industry, electrical industry, etc., and play a role in replacing steel with steel. Wood, efficient construction, energy saving, pollution prevention and other good effects.

Color-coated steel plates using galvanized steel plates as the base plate, in addition to zinc protection, the organic coating on the zinc layer plays a covering and isolation role, which can prevent the steel plates from rusting and has a longer service life than galvanized steel plates. According to reports, the coating The service life of steel plates is 50% longer than galvanized steel plates.

However, in different regions and usage areas, the service life of colored coated plates with the same amount of galvanizing, the same coating, and the same coating thickness will vary greatly. For example, in industrial areas or coastal regions, the corrosion rate is accelerated and the service life is affected due to the action of sulfur dioxide gas or salt in the air. During the rainy season, if the coating is soaked in rainwater for a long time or in areas where the temperature difference between day and night is too large and prone to condensation, it will corrode quickly and its service life will be reduced.

CREDIT