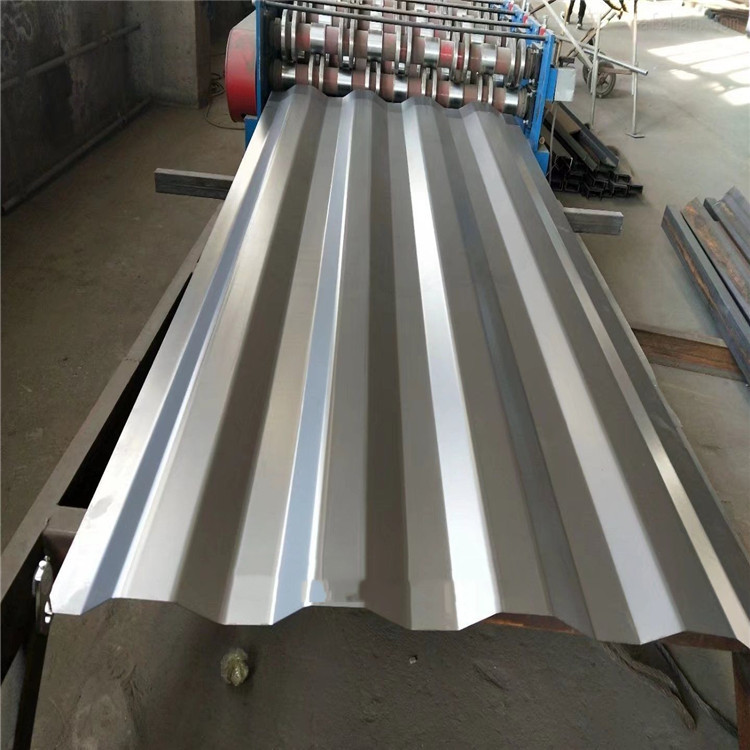

Aluminum Corrugated Roofing Sheets is composed of an aluminum-zinc alloy structure, which is composed of 55% aluminum, 43% zinc and 2% silicon solidified at 600℃. Its entire structure is composed of aluminum-iron-silicon-zinc, forming a dense quaternary crystal alloy. The thermal reflectivity of galvanized steel sheet is very high, twice that of galvanized steel sheet, and people often use it as a heat insulation material.

Aluminum Corrugated Roofing Sheets usually have the following characteristics:

1. Super corrosion resistance: The corrosion resistance of galvanized steel sheets is 6-8 times that of ordinary galvanized sheets, and it is usually guaranteed not to rust for 20 years.

2. High temperature oxidation resistance: Galvanized steel sheets will not change color or deform even if used for a long time in a high temperature environment of 315 degrees Celsius.

3. High thermal reflectivity: The thermal reflectivity of galvanized steel sheets is higher than 75%, which is about twice that of galvanized sheets. When used as roofs and panels without painting, it can achieve energy-saving effects. Easy processing: It can meet the requirements of stamping, shearing, bending and other processing.

4. Beautiful appearance: The silver-white snowflake pattern is beautiful and can be used directly without painting.

5. Surface spraying is possible: Galvanized steel sheets are good substrates for paint coating, and the composite coating of alloys and organic matter can provide more efficient protection and prevent rust.

6. More usable area: The specific gravity of the galvanized steel plate (3.75g/m3) is much smaller than that of zinc (7.15g/m3). Therefore, when the steel substrate and the coating thickness are the same, each ton of galvanized steel plate has a much larger usable area than galvanized steel plate, which provides greater benefits to users.

Every 1,000 tons of AZ150 galvanized steel plate is equivalent to:

(1) 1,050 tons of 0.3mm thick galvanized steel plate.

(2) 1,035 tons of 0.5mm thick galvanized steel plate (3) 1,025 tons of 0.7mm thick galvanized steel plate.

CREDIT

The difference between aluminum corrugated roofing sheets and galvanized sheet:

(1) 55% aluminum-zinc alloy-coated galvanized steel sheet has better corrosion resistance than galvanized steel sheet of the same thickness when both sides are exposed to the same environment. 55% aluminum-zinc alloy-coated galvanized steel sheet not only has good corrosion resistance, but also has excellent adhesion and flexibility.

(2) The difference between galvanized sheet and galvanized sheet mainly lies in the difference in coating. A layer of zinc material is evenly distributed on the surface of the galvanized sheet, which plays an anodic protection role for the parent material. That is to say, the alternative corrosion of zinc material protects the use of the parent material. Only when the zinc is completely corroded can the parent material inside be damaged.

(3) The surface coating of galvanized sheet is composed of 55% aluminum, 43.5% zinc and a small amount of other elements. Under the microscopic level, the surface of galvanized coating is a honeycomb structure, and zinc is contained in the "honeycomb" composed of aluminum. In this case, although the galvanized coating also plays the role of anodic protection, on the one hand, due to the reduction of zinc content and on the other hand, due to the fact that the zinc material is wrapped in aluminum and is not easy to electrolyze, the role of anodic protection is greatly reduced. Therefore, once the galvanized sheet is cut, the cut edge will quickly rust under the condition of basically losing protection. Therefore, the galvanized sheet should be cut as little as possible. Once cut, anti-rust paint or zinc-rich paint should be used to protect the edge to extend the service life of the sheet.

CREDIT

Aluminum Corrugated Roofing Sheets are generally used in:

(1) Buildings: roofs, walls, garages, soundproof walls, pipes and modular houses, etc.

(2) Automobiles: mufflers, exhaust pipes, wiper accessories, fuel tanks, truck boxes, etc.

(3) Home appliances: refrigerator back panels, gas stoves, air conditioners, electronic microwave ovens, LCD frames, CRT explosion-proof belts, LED backlights, electrical cabinets, etc. Agricultural use: pig houses, chicken houses, granaries, greenhouse pipes, etc.

(4) Others: thermal insulation covers, heat exchangers, dryers, water heaters, etc.