Metal roofing panels have emerged as a premier choice in contemporary construction, renowned for their exceptional durability, longevity, and aesthetic versatility. Primarily manufactured from materials such as galvanized steel, aluminum, zinc, copper, or stainless steel, these panels are engineered to form a robust, protective, and often striking exterior for a wide range of structures, from residential homes to vast industrial complexes.

General size

Valid Length:800-1500mm

Thickness:0.1-1mm

Core strength

The core strength of metal roofing lies in its performance. These panels are designed to withstand extreme weather conditions, including heavy snow, hail, high winds, and torrential rain. Their interlocking seam systems provide superior waterproofing capabilities. A key advantage is their exceptional fire resistance, offering a significant safety benefit. Furthermore, most metal roofs are coated with highly reflective finishes. These coatings, often based on PVDF (Polyvinylidene Fluoride) or SMP (Silicone Modified Polyester) resins, not only provide a vast array of color and finish options—from matte to metallic—but also contribute to energy efficiency. By reflecting a substantial portion of solar radiant heat, they help reduce cooling costs during summer months, making them an environmentally conscious choice.

Durability is another hallmark. A properly installed and maintained metal roof can last 40 to 70 years, far exceeding the lifespan of traditional asphalt shingles. They are resistant to corrosion, cracking, and shrinking, and they shed snow and rain effectively. The panels are also lightweight compared to materials like concrete tile or slate, which can simplify the structural support requirements of a building.

Sustainability

From a sustainability perspective, metal roofing is highly favorable. Most panels are made from a significant percentage of recycled content and are themselves 100% recyclable at the end of their long service life, minimizing landfill waste.

Installation design

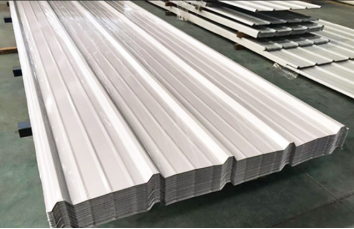

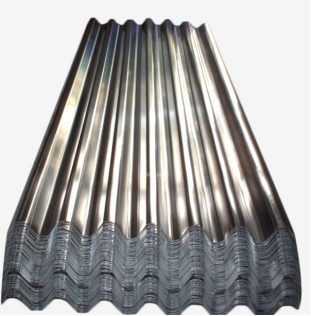

Installation is typically done over a battens/counter-battens system, which creates a ventilated air gap between the panel and the roof deck. This crucial feature helps manage condensation and improves thermal performance. The most common profiles include the classic standing seam, with its concealed fasteners and clean vertical lines, and the through-fastened corrugated panel, known for its strength and economical value.

In conclusion, metal roofing panels represent a sophisticated fusion of resilience, efficiency, and design flexibility. They offer a long-term, low-maintenance, and sustainable building solution that meets the demanding performance standards of modern architecture while providing enduring protection and beauty.