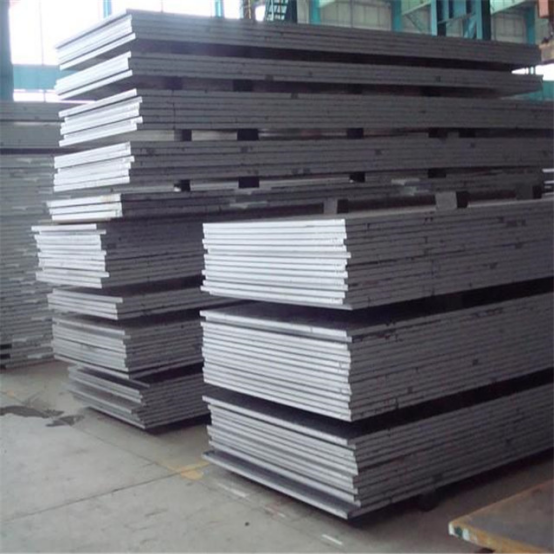

Hot Rolled Steel Plate: Production Process, Properties, and Industrial Applications

Manufacturing Process – High Temperature Rolling – Surface Scale

Hot rolled steel plate is a fundamental product in the steel industry, widely used in construction, machinery, shipbuilding, and pressure vessels. It is manufactured through a process that involves rolling steel slabs at high temperatures—typically above 900°C, which is higher than the steel’s recrystallization point. During the manufacturing process, the slab is reheated in a furnace and then passed through a series of rollers to achieve the desired thickness and width. This high temperature rolling allows the steel to be shaped easily and reduces energy consumption during deformation. However, the process also causes a layer of surface scale—a thin layer of oxide that forms when the hot steel reacts with oxygen in the air. Although this scale slightly affects surface smoothness, it can be removed by pickling or further processing, depending on the final use requirements. Overall, the hot rolling process provides efficiency, lower production costs, and flexibility in producing various sizes of plates.

One of the major advantages of hot rolled steel plate is its combination of mechanical strength and excellent ductility. Due to the high-temperature processing, the steel’s microstructure becomes uniform and tough, enabling it to withstand heavy loads and resist impact. Hot rolled plates are therefore widely used in situations where strength and durability are essential, such as in bridges, heavy machinery, and structural frameworks. However, compared with cold rolled steel, hot rolled products have lower dimensional accuracy and rougher surfaces because of the thermal expansion and contraction that occur during cooling. For applications requiring precise dimensions and smooth finishes, hot rolled plates are often further processed through cold rolling, leveling, or surface treatment. Despite this limitation, the superior mechanical properties and workability of hot rolled steel make it the preferred material for most industrial and construction purposes, especially when tight tolerances are not the main concern.

The versatile applications of hot rolled steel plate make it indispensable across numerous industries. In the construction field, it is used for building frames, platforms, and steel bridges due to its high load-bearing capacity. In the manufacturing sector, it serves as a base material for producing pipes, tanks, pressure vessels, and ship hulls. The cost efficiency of hot rolled steel also contributes to its popularity—its production process is simpler and cheaper than cold rolling, making it ideal for large-scale structural projects. Furthermore, as global industries focus more on sustainability, the steel sector is moving toward greener production technologies, such as energy-efficient reheating furnaces and the use of recycled scrap. These innovations will enhance the future development of hot rolled steel plate, improving its quality, reducing emissions, and promoting circular economy practices. As a result, hot rolled steel will continue to play a key role in modern industrial progress and infrastructure development worldwide.