I:define

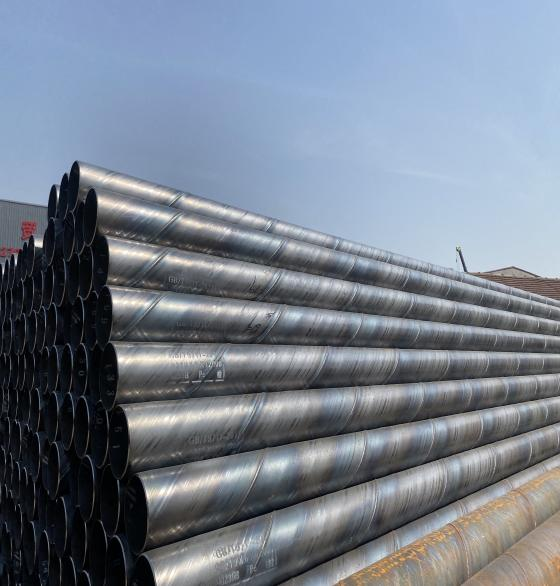

Spiral pipe, also known as spiral steel pipe or spiral welded pipe, is made by rolling low-carbon structural steel or low-alloy structural steel strip into a pipe blank at a certain angle of the spiral line (called forming angle), and then welding the pipe seam together. It can produce large-diameter steel pipes with narrower strip steel.

II:purpose

Spiral tubes are mainly used in water engineering, petrochemical industry, chemical industry, power industry, agricultural irrigation, and urban construction, and are one of the twenty key products developed domestically. Used for liquid transportation: water supply, drainage, sewage treatment engineering, mud transportation, ocean water transportation. Used for gas transportation: coal gas, steam, liquefied petroleum gas. Used for structural purposes: as pile driving pipes, as bridges; Pipes for docks, roads, building structures, marine pile driving pipes, etc.

Spiral tubes are mainly used in water engineering, petrochemical industry, chemical industry, power industry, agricultural irrigation, and urban construction, and are one of the twenty key products developed domestically.

Used for liquid transportation: water supply, drainage, sewage treatment engineering, mud transportation, ocean water transportation.

Used for gas transportation: coal gas, steam, liquefied petroleum gas.

Used for structural purposes: as pile driving pipes, as bridges;

Pipes for docks, roads, building structures, marine pile driving pipes, etc.

III:characteristic

Characteristics of Spiral Pipe: The production process of straight seam welded pipe is simple, with high production efficiency, low cost, and rapid development.

The strength of spiral welded pipes is generally higher than that of straight seam welded pipes. It can produce welded pipes with larger diameters using narrower billets, and can also produce welded pipes with different diameters using billets of the same width.

However, compared to straight seam pipes of the same length, the weld seam length increases by 30-100%, and the production speed is lower.

Therefore, smaller diameter welded pipes mostly use straight seam welding, while large-diameter welded pipes mostly use spiral welding.