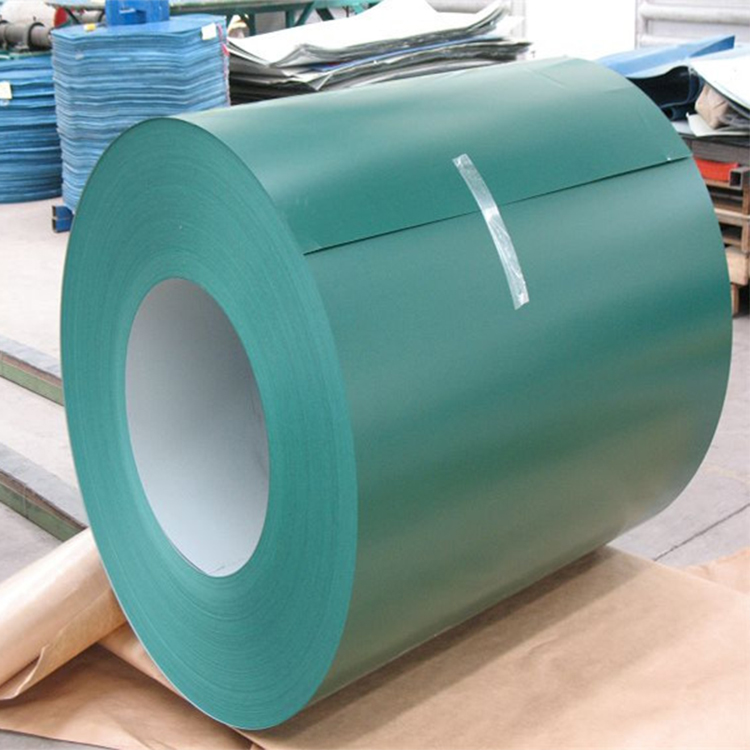

PPGI (Pre-Painted Galvanized Iron) coil is a high-quality steel product produced by coating steel sheets with one or more layers of organic paint, followed by high-temperature baking to cure the coating. The base materials commonly include hot-dip galvanized sheets, hot-dip aluminum-zinc sheets, and electro-galvanized sheets. The applied coatings provide excellent corrosion resistance, aesthetic appeal, and superior workability.

CREDIT

Thanks to its excellent durability and decorative properties, PPGI coil is widely used across various industries:

l Construction Industry: Roof panels, wall claddings, doors & windows, curtain walls.

l Home Appliances: Refrigerator panels, washing machine bodies, air conditioner casings.

l Automotive Industry: Exterior body parts, interior trims.

l Furniture Industry: Cabinet panels, door surfaces.

l Advertising Industry: Billboards, display racks.

l Corrosion Resistance: The coating acts as a protective barrier against environmental damage, greatly enhancing the steel's durability.

l Aesthetic Versatility: Available in a wide range of colors and finishes to meet diverse design needs.

l Excellent Processability: Suitable for cutting, bending, stamping, and other fabrication processes.

l Weather Resistance: Withstands harsh environmental conditions, including UV rays, rain, and temperature fluctuations.

Item | Range |

Substrate Material | Hot-dip galvanized, Hot-dip Alu-Zinc, Electro-galvanized |

Coating Types | Polyester, Polyurethane, PVDF (Fluorocarbon), etc. |

Coating Thickness | Customized per usage environment |

Base Metal Thickness | 0.20mm – 2.00mm |

Width | 700mm – 1500mm |

Color Options | Various RAL colors and customized finishes |

l Hot-Dip Galvanized PPGI Coil: Superior corrosion resistance, widely used for general construction.

l Hot-Dip Alu-Zinc PPGI Coil: Exceptional durability in harsh environments, ideal for coastal and industrial applications.

l Electro-Galvanized PPGI Coil: Cost-effective option, suitable for interior or less demanding environments.