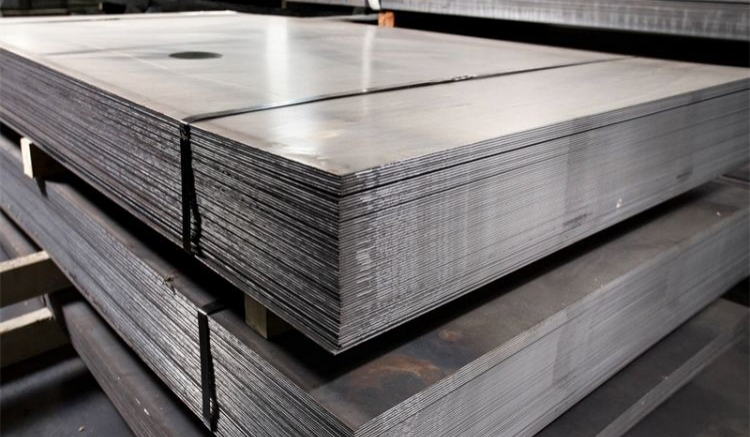

Hot-rolled plate

Product introduction:

Hot-rolled plate is a type of steel sheet produced by rolling steel slabs at elevated temperatures. During manufacturing, the steel billet undergoes per-treatment and is then continuously passed through a rolling mill while hot. This high-temperature process refines the grain structure of the steel and enhances its mechanical properties through thermal and mechanical treatment. As a result, hot-rolled plates offer improved strength, form-ability, and durability. Due to their excellent wear resistance, heat resistance, and strength, as well as their cost efficiency, hot-rolled plates are widely utilized in industries such as construction, bridge engineering, automotive manufacturing, and pipeline production.

CREDIT

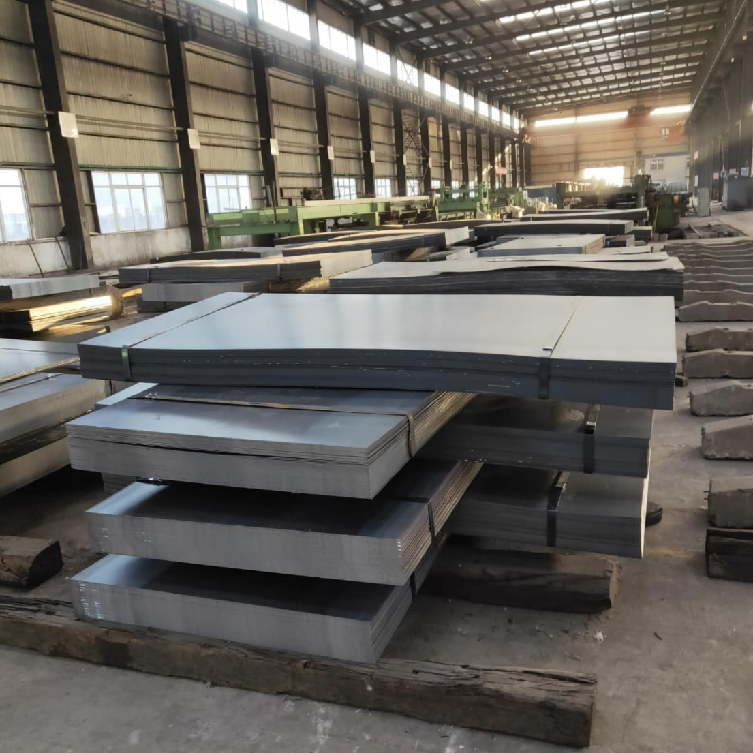

Structural steel plate

Common product specifications:

Hot-rolled plates typically have a thickness ranging from 2mm to 200mm, with widths between 600mm and 2500mm, and lengths generally spanning from 2000mm to 12000mm. Standard sizes include, but are not limited to, 3mm, 5mm, 8mm, 10mm, 12mm, 16mm, and 20mm. In addition, customized dimensions can be produced based on specific customer requirements.

Product application:

Hot-rolled plates are extensively used across a wide range of industries, including construction, steel structure engineering, automotive manufacturing, shipbuilding, pipeline production, oil and gas extraction, and heavy machinery. In the construction sector, they are commonly used for structural components such as staircases, ceilings, and wall panels. In the automotive industry, they serve in the production of vehicle body frames and chassis parts. In shipbuilding, they are applied in the fabrication of hull structures and related fittings. For pipeline manufacturing, hot-rolled plates are used to produce pipes for transporting oil, gas, and various liquids.

High-strength steel plate

Product advantages:

Outstanding Mechanical Properties: Hot-rolled plates offer high strength, excellent toughness, and strong fatigue resistance, making them ideal for applications that demand durability and structural integrity.

Superior Work-ability: These plates can be easily processed through cutting, stamping, welding, and other fabrication methods, allowing them to meet the requirements of complex structural designs.

Excellent Weather and Corrosion Resistance: Hot-rolled plates maintain stable performance even in harsh environments, thanks to their strong resistance to weathering and corrosion over long-term use.

Quality inspection process:

We adhere strictly to international quality standards throughout our inspection process, which includes appearance checks, dimensional measurements, chemical composition analysis, and mechanical performance testing. These rigorous procedures ensure that every batch of products fully complies with the customer's technical specifications and quality requirements.

Product development prospects:

With the rapid pace of global industrialization, the demand for hot-rolled plates continues to rise. Looking ahead, advancements in science and technology, along with the intelligent upgrading of the manufacturing sector, will further enhance the role of hot-rolled plates in areas such as energy efficiency, emissions reduction, lightweight construction, and high-strength applications. As a result, they will offer more advanced and sustainable material solutions across a wide range of industries.