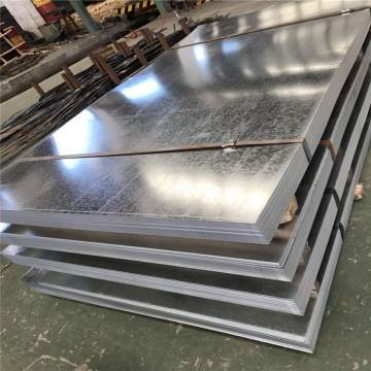

Galvanized steel sheet, also known as zinc-coated steel sheet, is a type of steel sheet with a layer of metallic zinc applied to its surface through either hot-dip galvanizing or electroplating processes. This coating is primarily designed to prevent corrosion of the steel surface, thus prolonging its service life. Galvanized steel sheets are widely used in various industries due to their excellent corrosion resistance, durability, and relatively low cost.

Galvanized steel sheets find extensive applications in: Construction: As roofing materials, wall panels, and structural components in buildings and infrastructure projects. Automotive Industry: In vehicle bodies, chassis components, and parts requiring corrosion resistance. Appliances: For manufacturing household appliances such as refrigerators, washing machines, and air conditioners. Containers and Packaging: In the production of drums, cans, and other containers requiring durability and corrosion resistance. Agriculture: For fencing, silos, and other structures exposed to harsh environments.

Galvanized steel sheets come in various specifications, including: Thickness: Typically ranging from 0.3mm to 3.0mm, but can vary based on customer requirements. Width and Length: Standard widths can be up to 1500mm, with lengths determined by the application and manufacturing process. Custom sizes are also available. Zinc Coating Weight: Measured in grams per square meter (g/m²), common coatings range from 60g/m² to 275g/m² or more, depending on the intended use and corrosion resistance requirements. Surface Finish: Available in regular spangle, fine spangle, smooth spangle, no-spangle, and phosphating surfaces.

Corrosion Resistance: The zinc coating effectively protects the steel from rust and corrosion, even in harsh environments.

Durability: Galvanized steel sheets have a long service life, reducing the need for frequent replacements.

Cost-Effectiveness: Compared to other corrosion-resistant materials, galvanized steel sheets offer a cost-effective solution.

Versatility: Available in various thicknesses, widths, and coating weights, suitable for a wide range of applications.

Easy Processing: Can be easily cut, bent, and welded, making it suitable for various fabrication processes.

TREND AND PROSPECT

Growing Demand in Developing Economies: Rapid urbanization and infrastructure development in countries like China, India, and Brazil are driving significant growth in the demand for galvanized steel sheets.

Increasing Use in Automotive Industry: The automotive industry's shift towards lightweight and fuel-efficient vehicles is driving the adoption of galvanized steel sheets due to their lightweight properties and corrosion resistance.

Sustainable Production: Environmental concerns and regulations are encouraging the industry to shift towards sustainable galvanized steel production methods, such as using recycled zinc and reducing energy consumption during manufacturing.

Innovation in Coatings: Developments in coating technologies, such as alloy-coated galvanized steel sheets, are providing improved corrosion resistance and other enhanced properties.

INSPECTION STANDARD

Galvanized steel sheets are subject to various international and national standards, including:

ASTM A653/A653M: Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the Hot-Dip Process.

EN 10142: Hot-dip galvanized structural steel sheet and strip with improved atmospheric corrosion resistance.

JIS G3302: Hot-dip zinc-coated steel sheet and strip.

These standards specify requirements for coating weight, surface appearance, mechanical properties, and other relevant characteristics of galvanized steel sheets. Manufacturers and end-users typically adhere to these standards to ensure product quality and consistency.

Previous: ERW Welded Steel Pipe

Next: Galvalume Steel Coils