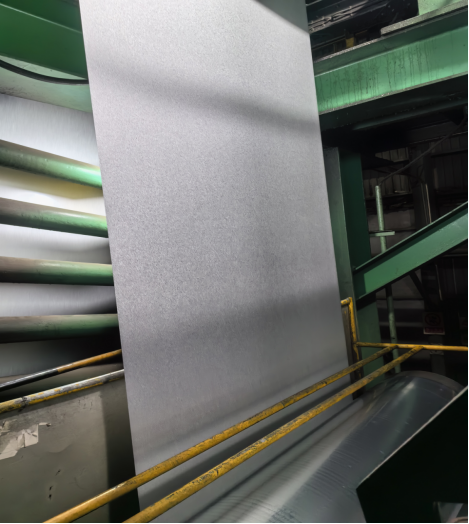

Galvalume steel coils, a high-performance metal product, are made by coating cold-rolled steel with an aluminum-zinc alloy. The typical composition includes 55% aluminum, 43.5% zinc, and 1.5% silicon, offering superior corrosion resistance and a longer lifespan compared to traditional galvanized products.

Commonly available in widths from 610mm to 1500mm and thicknesses ranging from 0.2mm to 2.0mm, these coils are versatile and widely used. They find applications in roofing and wall panels, gutters, downspouts, and building facades. Additionally, their use extends to automotive, appliance, and general manufacturing sectors.

The key advantage of Galvalume steel coils lies in their enhanced corrosion resistance, which can be up to six times that of galvanized steel. This feature, combined with their paintability and formability, makes them a preferred choice for a variety of applications.

Market trends indicate a growing demand for Galvalume steel coils due to their durability and sustainability. As the construction industry shifts towards greener building materials, the use of these coils is expected to rise, driven by their recyclability and reduced environmental impact.

Quality control is paramount in the production of Galvalume steel coils. Stringent quality assurance processes, including chemical analysis, mechanical testing, and surface inspection, ensure that the coils meet international standards. This rigorous quality control guarantees the product's integrity and performance in various applications.

In conclusion, Galvalume steel coils, with their robust specifications, versatile applications, and environmental advantages, are poised to play a significant role in the future of construction and manufacturing. Their durability and sustainability make them a smart investment, ensuring long-term benefits for both the industry and the environment.

Previous: GI SHEETS

Next: Galvanized Steel Sheets