INTRODUCTION

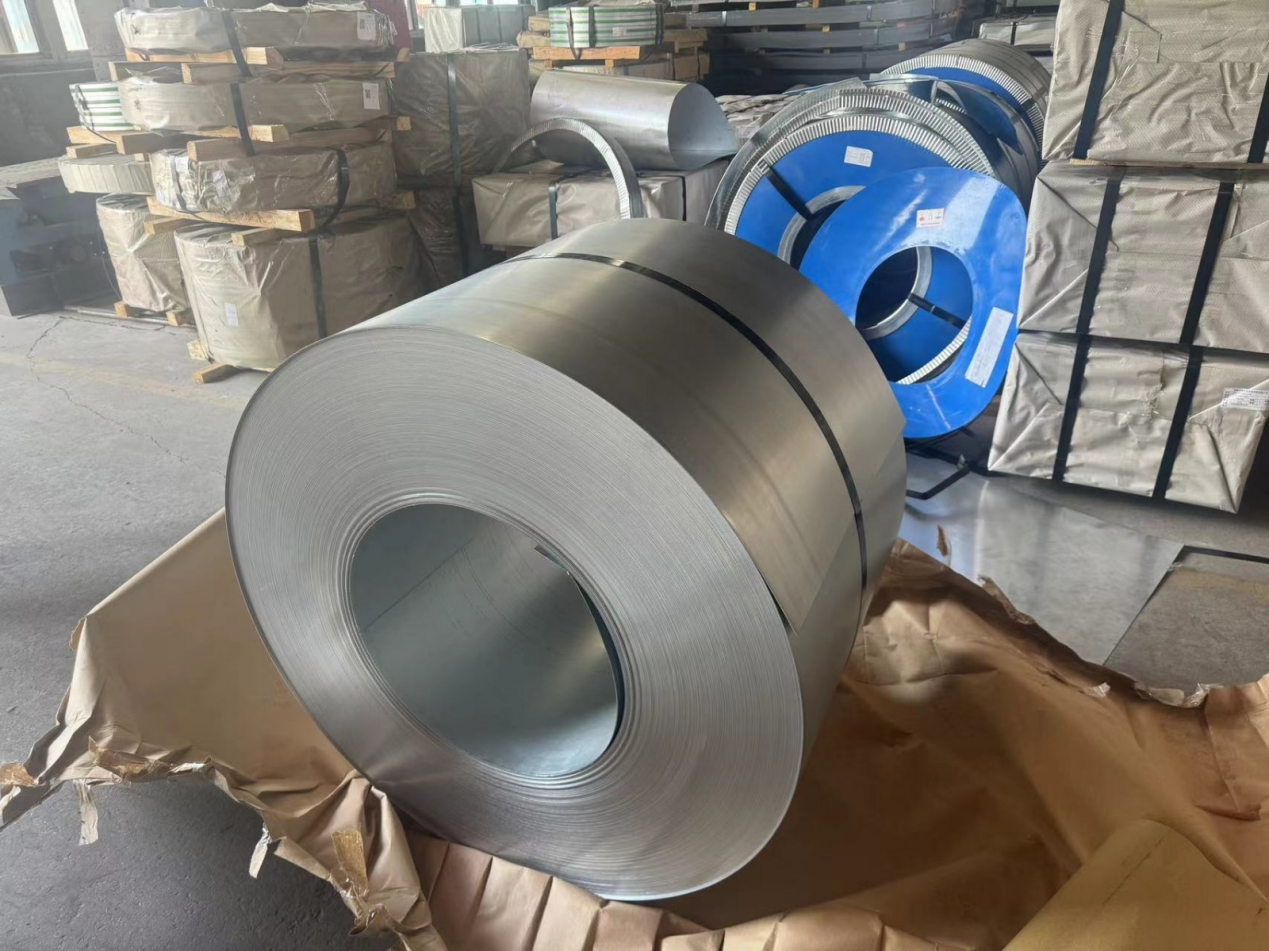

Galvanized steel coils, often called galvanized steel sheets or coils, are steel sheets coated with a protective layer of zinc through a galvanizing process. Typically produced via hot-dip galvanizing, this method involves dipping cleaned steel sheets into molten zinc, allowing the zinc to bond metallurgic-ally with the steel surface. The final product retains the durability and work-ability of steel while gaining enhanced rust resistance from the zinc coating.

APPLICATION AND SPECIFICATION

Galvanized steel coils are a highly adaptable material widely used in multiple industries. In construction, they serve as essential structural elements—including beams, columns, and purl ins—as well as durable roofing and wall panels, providing excellent resistance to corrosion from moisture and weather exposure. These coils are available in a variety of specifications to meet different requirements.

Thickness options typically range from 0.15mm to 4.5mm, with common choices such as 0.2mm, 0.3mm, 0.5mm, 1.0mm, 1.5mm, 2.0mm, and 3.0mm.

Widths can be customized, with standard sizes including 1000mm, 1250mm, and 1500mm, usually not exceeding 1.5 meters.

Lengths also vary, frequently offered in 2000mm, 2500mm, and 3000mm, with most coils staying under 6 meters in length.

CREDIT

ADVANTAGES

Superior Corrosion Protection: The zinc coating creates an effective shield against moisture, oxygen, and other corrosive agents, greatly extending the steel's service life.

Attractive Finish: The galvanized surface boasts a bright, silvery sheen, improving the aesthetic quality of finished products.

Enhanced Longevity: The zinc layer can increase the lifespan of bare steel by two to three times.

Excellent Work-ability: These coils can be easily cut, formed, and welded, making them highly adaptable for diverse fabrication needs.

Eco-Friendly & Safe: The material offers reliable fire resistance and can be manufactured using sustainable methods, aligning with modern environmental and safety standards.

TREND AND PROSPECT

The market for galvanized steel coils is experiencing steady growth, driven by economic progress and industrial transformation. As galvanizing technology advances and governments worldwide promote manufacturing upgrades, the industry presents significant growth potential. Investors can anticipate attractive returns and sustainable development opportunities, thanks to the material's versatile applications and stable market demand.

INSPECTION STANDARD

Galvanized steel coils undergo rigorous quality inspections and are classified into different grades to ensure consistent standards. The classification system typically includes:

First-grade (Premium) – Meets strict specifications with only minor permissible defects that don't affect performance

Second-grade (Commercial) – Acceptable under buyer-seller agreement, with slightly more visible imperfections

Third-grade (Utility) – Functional but with noticeable defects, suitable for less demanding applications

Waste – Rejected due to critical flaws like severe rust, zinc peeling, or edge damage

This tiered evaluation system guarantees market-ready products meet defined quality benchmarks, protecting end-users while maintaining industry reliability.