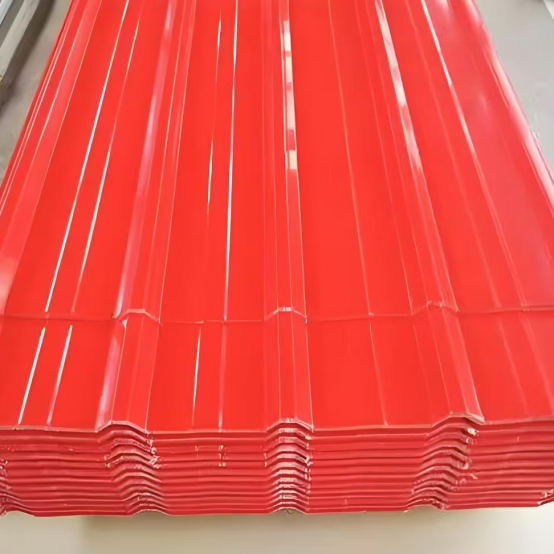

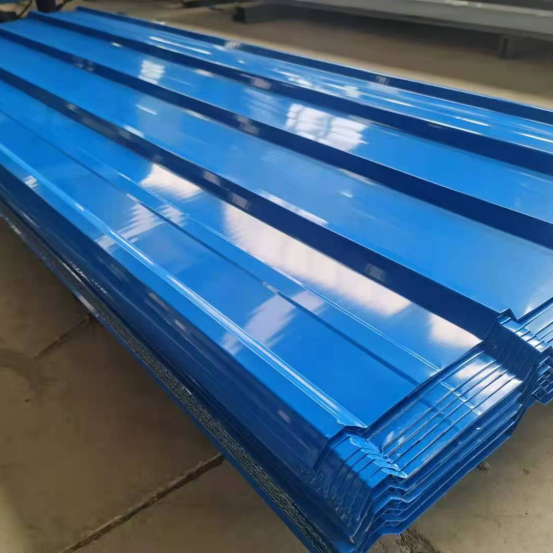

Color Coated Steel Corrugated Sheets are durable and attractive steel panels coated with vibrant paint. Ideal for roofing and walls, they offer excellent weather resistance, corrosion protection, and easy installation. Perfect for industrial, commercial, residential, and agricultural use.

Specifications and types

Color-coated corrugated steel sheet is a high-performance material widely used in modern buildings. It is mainly composed of a steel sheet substrate and a colored coating. Common specifications include thickness ranging from 0.3mm to 1.2mm, width usually from 600mm to 1200mm, length can be extended from 2000mm to 6000mm according to demand, and wave height has a variety of options such as 18mm, 25mm, 28mm, etc. The flexibility of these specifications allows color-coated corrugated steel sheets to adapt to the needs and design requirements of different buildings.

Anti-Corrosion Color Steel Sheets

Product application

Color-coated corrugated steel sheets are widely used, covering industrial plants, commercial buildings, residential areas, storage facilities, agricultural facilities and other fields. In industrial plants, color-coated corrugated steel sheets as roof and wall materials provide excellent durability and aesthetics, meeting the needs of industrial buildings for large spans and high strength. In commercial buildings such as shopping malls and office buildings, the diverse color and texture options of color-coated corrugated steel sheets make the appearance of the buildings more modern and attractive. In residential buildings, especially family houses and villas, the excellent thermal insulation and sound insulation properties of color-coated corrugated steel sheets can effectively improve living comfort. In addition, in agricultural facilities such as greenhouses and farms, the corrosion resistance and weather resistance of color-coated corrugated steel sheets ensure their stable performance in various environments.

Eco-Friendly Color Coated Steel Panels

Product Quality Inspection Process

In terms of quality inspection, the production process of color-coated corrugated steel sheets is strictly controlled to ensure product quality. The quality inspection process includes raw material inspection, coating inspection, dimension measurement, appearance inspection, mechanical property test and finished product inspection. Through strict inspection of each batch of raw materials, inspection of coating adhesion and weather resistance, precise measurement of product dimensions, detection of surface defects, mechanical property test and final finished product inspection, it is ensured that every piece of color-coated corrugated steel sheets shipped out of the factory meets high quality requirements.

Market development trends and prospects

Looking ahead, the market prospects for color-coated corrugated steel sheets are very broad. With the continuous development of the construction industry and the increasing requirements for green environmental protection, color-coated corrugated steel sheets, as an environmentally friendly and energy-saving building material, will gain more and more market attention. Technological innovation will promote the diversification of its functions, such as more efficient thermal insulation and sound insulation performance and the application of new coating materials, further enhancing the market competitiveness of products. In addition, the market demand for personalized and customized products continues to increase, and color-coated corrugated steel sheets will also provide more customization options to meet the needs of different customers. The growth of the global construction market, especially the increase in construction demand in developing countries, will promote the market expansion of color-coated corrugated steel sheets and strengthen its important role in the construction industry.

Previous: Galvalume roofing sheets

Next: ERW Welded Steel Pipe