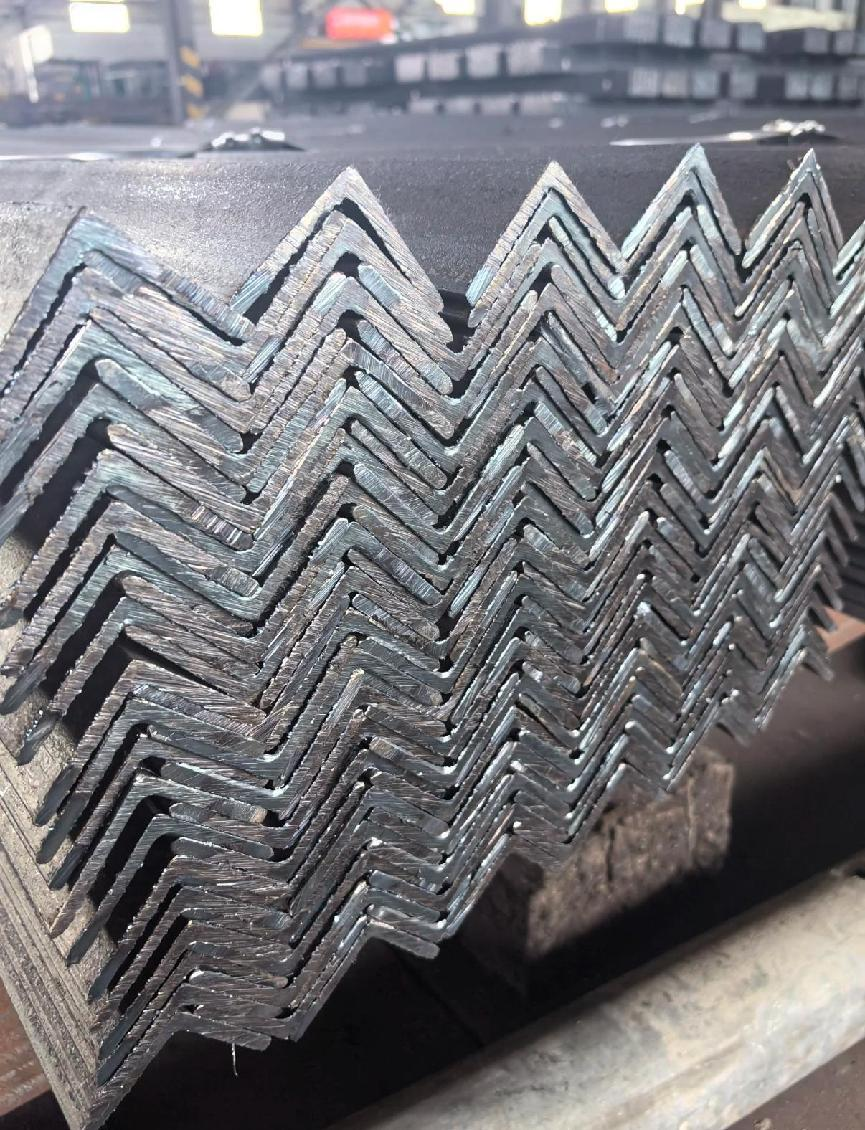

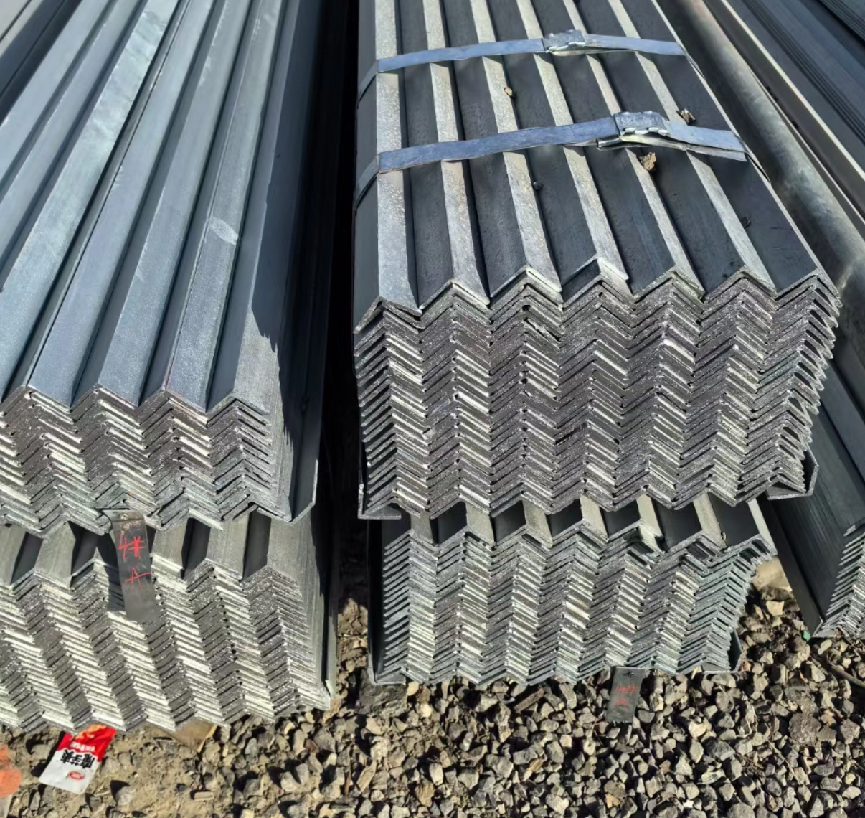

Angle steel, commonly known as angle iron, is a type of long strip steel with two sides perpendicular to each other, widely used in construction, bridges, machinery manufacturing, transportation, power, and other fields. Depending on whether the two sides have equal widths, angle steel can be divided into equal-leg angle steel and unequal-leg angle steel. The specifications of equal-leg angle steel are usually indicated by the side width multiplied by the side thickness, for example, "∟30×30×3" represents an equal-leg angle steel with a side width of 30mm and a side thickness of 3mm. The model number of angle steel is also a way to represent its specifications, but it does not cover the size information of different side thicknesses within the same model.

Angle steel comes in a wide range of specifications. Common equal-leg angle steel specifications range from No. 2 to No. 20, with side widths from 20mm to 200mm and side thicknesses from 3mm to 24mm. The specification range varies depending on the grade of angle steel, such as Q235, Q345, SS400, A36, etc. The choice of these specifications depends on the specific application scenario and requirements.

CREDIT

Angle steel has a wide range of applications, including but not limited to:

1. Building Structures: Used for staircase handrails, staircase steps, platform edge protection, ceiling supports, corner protection, and components of frames and supporting structures.

2. Vehicle Manufacturing: Used for vehicle chassis, frames, bodies, and other structural components to enhance vehicle stability and strength.

3. Machinery Manufacturing: Serves as support, connection, and fixing components for machinery equipment, such as machine tool beds, columns, and workbench supports.

4. Furniture Manufacturing: Used as support and connection components for furniture, such as table legs and chair armrests.

5. Shipbuilding: Used for manufacturing deck supports, hull frames, cabin partitions, etc.

6. Steel Structure Engineering: Used for manufacturing steel structure frames, beams, slabs, and other components.

Angle steel offers significant advantages:

1. Excellent Strength and Stability: With its unique right-angle cross-sectional structure and superior mechanical properties, angle steel can withstand large loads and deformations.

2. Easy Processing and Connection: The cross-sectional shape of angle steel facilitates connection and fixation with other components, improving the compactness and stability of the entire structure.

3. Wide Range of Applications: Angle steel is suitable for multiple industries and fields, meeting different usage requirements.

4. Cost-Effectiveness: Compared to other steel materials, angle steel offers high cost-performance, reducing engineering costs.

China's angle steel market size ranks first globally. In recent years, with the promotion of national policies and the acceleration of urbanization, the angle steel industry has undergone a leapfrog development from manual production to large-scale, intelligent manufacturing. In the future, the angle steel industry will exhibit the following development trends:

1. High-End, Intelligent, and Green Manufacturing: Driven by the "dual-carbon" goals and changes in international market demand, the angle steel industry is gradually transforming towards high-end, intelligent, and green manufacturing.

2. Product Structure Upgrade: From low-end bulk commodities to high-strength, corrosion-resistant, and intelligent special angle steel to meet the needs of high-end fields such as super high-rise buildings and deep-sea platforms.

3. Green Manufacturing System: Reducing unit energy consumption through technologies such as short-process steel-making and waste heat recovery to build a green manufacturing system.

4. Deepening International Cooperation: Establishing a global supply chain network covering raw material procurement, production, and sales to deepen international cooperation and circumvent trade barriers.

CREDIT

The quality inspection process for angle steel typically includes the following steps:

Inspection Requirements upon Arrival: Upon arrival, the purchaser should fill out an inspection request form for the inspector and simultaneously request material reports and certificates of conformity from the supplier.

Sampling Plan: Adopt a sampling inspection method, with the number of samples determined based on the quantity of incoming goods, but ensuring that the sampled angle steel meets the inspection item requirements.

Surface Quality: Visually inspect the surface of the angle steel for harmful defects such as lamination, scabs, cracks, etc.

Dimensional Measurement: Use calipers and other tools to measure the side width, side thickness, and other dimensions of the angle steel to ensure they meet standard requirements.

Mechanical Performance Testing: Assess the yield strength, tensile strength, toughness, and other mechanical properties of the angle steel through tensile tests, bending tests, and other methods.

Recording and Judgment: The inspector should record the inspection process and results and judge whether the angle steel is qualified according to standard requirements. If it is unqualified, handle it according to the nonconforming product control procedure.

In summary, as an important steel material, angle steel plays a crucial role in the construction, manufacturing, and other industries. With the constant changes in market demand and continuous technological advancements, the angle steel industry will continue to develop towards high-end, intelligent, and green manufacturing.