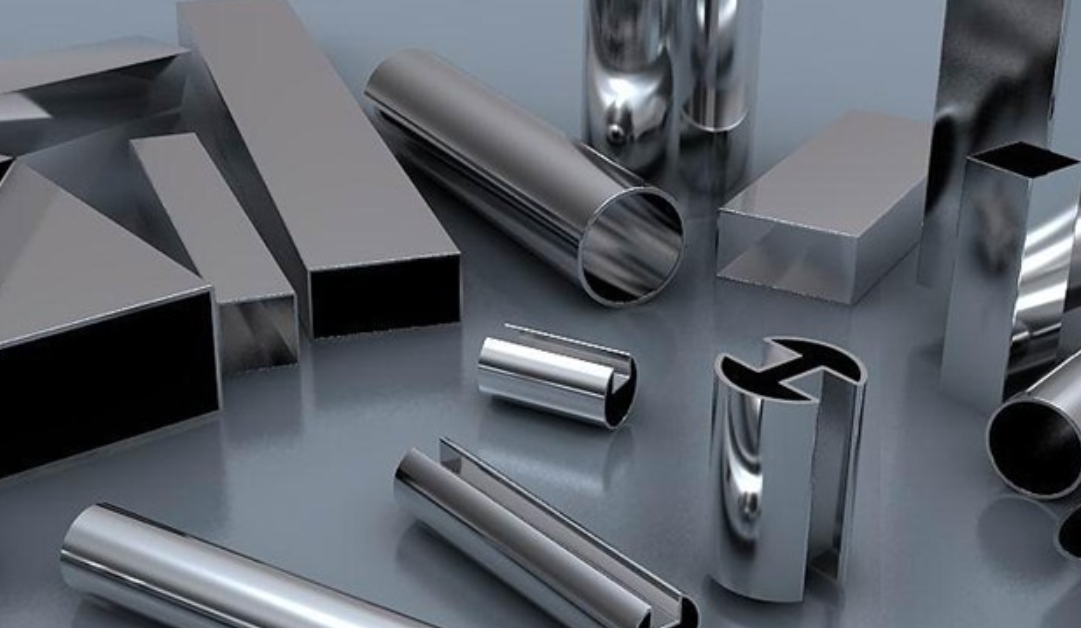

316S Stainless Steel Pipe: Detailed Explanation

Composition & Key Enhancements

316S is an austenitic stainless steel variant closely aligned with 316L, featuring a low carbon content (≤0.03%) to prevent carbide precipitation during welding, ensuring corrosion resistance in heat-affected zones. Its core alloy blend includes 16-18% chromium (forms a passive oxide layer), 10-14% nickel (boosts ductility and austenitic structure), and 2-3% molybdenum (critical for resisting chlorides, acids, and pitting). The "S" designation often denotes seamless manufacturing (SMLS) or aligns with regional standards (e.g., China’s GB/T 14976 for fluid transport).

CREDIT

Manufacturing & Types

Seamless Pipes: Produced via extrusion or rotary piercing, ideal for high-pressure/temperature applications (e.g., oil and gas).

Welded Pipes: Formed by rolling and welding sheets, cost-effective for moderate environments (e.g., architectural uses).

Superior Corrosion Resistance

The molybdenum addition makes 316S excel in aggressive settings:

Marine environments: Resists saltwater-induced pitting.

Chemical plants: Handles sulfuric/phosphoric acids and chlorides.

High-temperature stability: Performs up to 800°C (avoid prolonged exposure to 450-850°C to prevent sensitization).

Applications

Industrial: Chemical processing equipment, heat exchangers, and desalination plants.

Marine: Shipbuilding components, offshore platforms.

Food/Pharma: Hygienic tubing, sanitization-critical systems.

Architectural: Coastal structures, handrails exposed to moisture.

Standards & Grades

Complies with ASTM A312 (pipes) and A269 (tubing). Similar to 316L but may differ slightly in regional certifications (e.g., Japan’s SUS 316S).

Comparison to 316/316L

316: Higher carbon (≤0.08%); prone to weld decay.

316L/316S: Lower carbon (≤0.03%); better weld-ability and corrosion resistance post-fabrication.

Fabrication Tips

Welding: Use low-carbon filler metals (e.g., ER316L) to maintain integrity.

Machining: Austenitic structure causes work hardening; use sharp tools and slow speeds.

Sustainability

Fully recyclable, with long service life reducing replacement frequency.

In summary, 316S stainless steel pipe is a versatile, corrosion-resistant solution for harsh environments, combining the benefits of 316L with seamless manufacturing precision or regional standardization. Its adaptability across industries underscores its reliability in demanding applications.