Product Introduction and Common Specifications

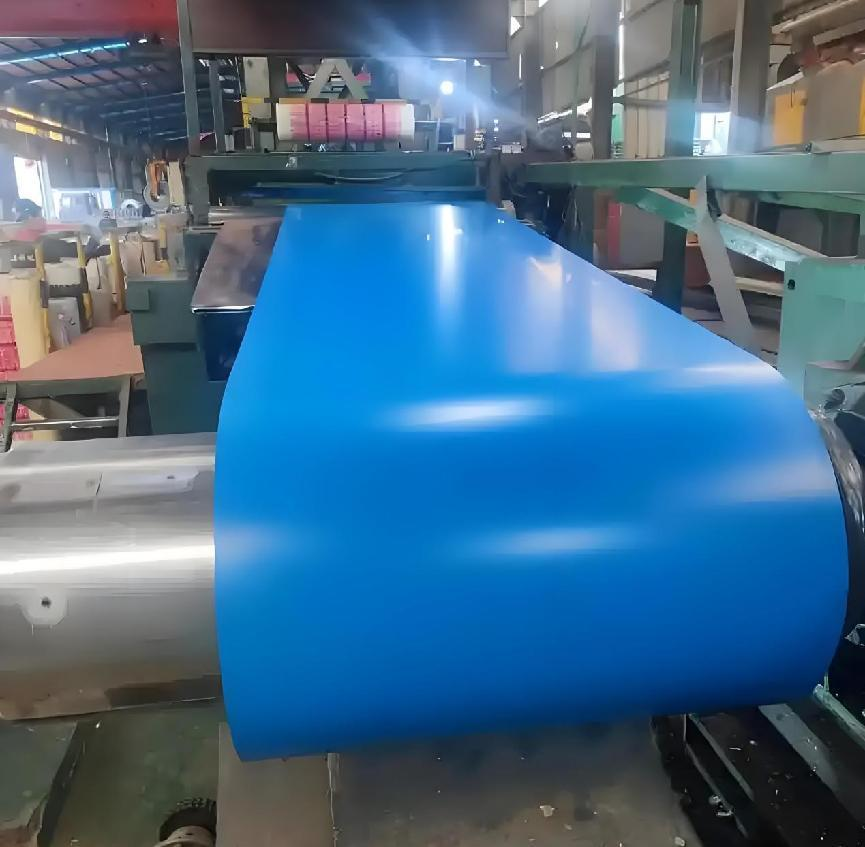

Color-coated coils, or color-coated steel coils, are steel plates that undergo a high-temperature baking process after an organic coating is applied to the surface of galvanized or galvalume substrates. These coils combine the strength of metal with a wide range of color options and a durable protective layer. As a result, they are extensively used in industries such as construction, home appliances, and transportation, making them a preferred material for modern industrial and architectural design.

Common color coated coil specifications include thicknesses between 0.2mm and 1.5mm, widths ranging from 600mm to 1250mm, and a variety of coating types, such as polyester (PE), silicon-modified polyester (SMP), high weather-resistant polyester (HDP) and polyvinylidene fluoride (PVDF), etc., which can meet the special needs of different customers.

Product Application and Advantages

Color-coated coils have a broad range of applications across various industries. In construction, they are commonly used for roofing, wall panels, rolling doors, and blinds. In the home appliance sector, color-coated coils are often found in products like refrigerators, washing machines, and air conditioner casings. In transportation, they are utilized in containers and both interior and exterior automotive trims. Additionally, color-coated coils are ideal for decorative and protective purposes in specialized environments such as cold storage, garages, and insulation boards.

The advantages of color-coated coils are mainly reflected in appearance, weather resistance, corrosion resistance, and environmental protection and energy saving. Its rich color and pattern selection can meet diverse decorative needs. At the same time, the anti-ultraviolet and anti-aging properties of color-coated coils enable them to adapt to harsh outdoor environments and extend their service life. Through advanced coating technology, color-coated coils have excellent corrosion resistance, meet green environmental protection standards, and help reduce energy loss.

CREDIT

Hot-Dip Galvanized Sheet

Product quality inspection methods

In order to ensure the quality of color-coated coils, the production process must undergo a strict quality inspection process. First, at the raw material stage, the steel substrate and the composition of the coating are strictly tested to ensure that the materials used meet national and industry standards. Then, during the production process, real-time monitoring is implemented, focusing on key indicators such as coating thickness, adhesion, and glossiness to ensure the uniformity and performance of the coating. In addition, the finished product inspection process includes simulated environmental tests such as salt spray resistance, corrosion resistance, and impact resistance to ensure that the product can be used safely and reliably in different environments. Through this series of strict quality inspection processes, the quality of color-coated coils is guaranteed to meet the market demand for high-quality products.

Market development trends

As the demand for aesthetically pleasing, durable, and environmentally friendly materials grows in the construction and industrial sectors, color-coated coils are evolving towards higher performance, sustainability, and smart technologies. In the future, there will be an increasing market demand for color-coated coils with enhanced weather resistance, eco-friendly coatings, and advanced features such as intelligent color-changing capabilities. These innovations will not only boost the competitiveness of products but also drive technological advancements within the industry. Moreover, as consumer demand for personalization and customization rises, the variety of colors and textures available in color-coated coils will expand further, better addressing the diverse needs of the market.

CREDIT