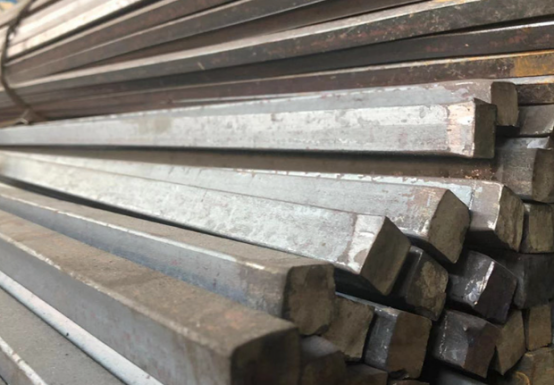

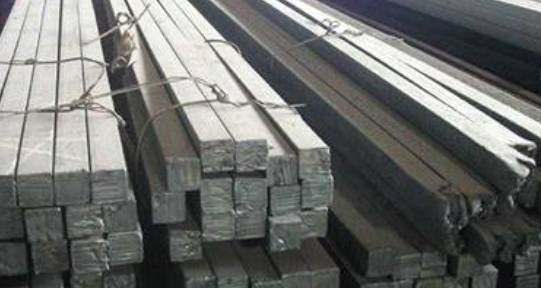

Square Steel

Square steel is a type of steel shaped into various forms and sizes through pressure processing, characterized by its square cross-section. Below is a detailed introduction to square steel:

By Material:

Carbon Structural Steel Square Steel: Primarily composed of carbon, it has good mechanical properties and is suitable for general construction and machinery manufacturing.

Low-Alloy High-Strength Square Steel: Contains a small amount of alloy elements (such as manganese, chromium, silicon, etc.) to enhance strength and wear resistance, suitable for load-bearing structures and applications requiring high strength.

Stainless Steel Square Steel: Primarily composed of chromium, it has corrosion resistance and high-temperature resistance, suitable for the chemical and food industries, particularly for refined decoration applications such as doors and windows.

Alloy Steel Square Steel: Contains multiple alloy elements, exhibiting specific physical and chemical properties, suitable for special applications and high requirements.

By Shape:

Square Steel: Cross-section is square or rectangular, suitable for load-bearing structures.

Hexagonal Steel: Cross-section is hexagonal, suitable for mechanical transmission components.

Unequal-Side Square Steel: Cross-section is asymmetric, suitable for special structures with limited space.

By Surface Treatment:

Black Square Steel: Raw steel without any surface treatment, inexpensive, suitable for general applications.

Epoxy Resin Coated Square Steel: Surface coated with epoxy resin, providing rust and corrosion resistance, suitable for outdoor applications.

Hot-Dip Galvanized Square Steel: Surface coated with a layer of zinc, providing excellent rust resistance, suitable for marine environments and the chemical industry.

By Production Process:

Hot-Rolled Square Steel: Side length range typically 5~250mm, processed using hot-rolling technology, which can refine steel grain, destroy cast structure, and help eliminate some internal defects.

Cold-Drawn Square Steel: Side length range typically 3~100mm, formed through cold drawing, bending, and other cold processing at room temperature, without damaging the coating on the steel surface, high production capacity, strong plasticity.

By Standard:

GB Square Steel: Produced according to Chinese national standards.

ASTM Square Steel: Produced according to American Society for Testing and Materials standards.

JIS Square Steel: Produced according to Japanese Industrial Standards.

Square steel comes in various specifications and models, such as 40×40mm, 50×50mm, 60×60mm, and 80×80mm. The side length range for hot-rolled square steel is typically 5250mm, while for cold-drawn square steel, it is typically 3100mm. Specification markings are usually indicated as cross-section a×cross-section a×length or simply cross-section a, for example, square steel 50×50×1000 or square steel 50, indicating a square steel with a cross-section of 50×50mm and a length of 1000mm.

Square steel has a wide range of applications, mainly in the following areas:

Lightweight Steel Structures: Such as steel roof frameworks and skeletons for residential buildings.

Machinery Manufacturing: Used to manufacture various mechanical parts, agricultural machinery accessories, tools, etc.

Shipbuilding: Also plays an important role in shipbuilding processes.

The theoretical weight calculation formula for hot-rolled square steel is: side length (mm) × side length (mm) × 0.00785 = kg/m. This formula helps users quickly calculate the weight of the required square steel, facilitating procurement and transportation.

In summary, square steel, as an important building material, has extensive applications in multiple fields. When purchasing and using square steel, users should select the appropriate material, shape, surface treatment, and specification model based on specific needs.