Greenhouse Steel Galvanized Pipe supplier shares this article for you.

Most of the domestic steel pipes are made of steel inside and hot-dip galvanized on the outside. Hot-dip galvanized is to increase the service life of anti-corrosion. The specific service life depends on four aspects.

Steel material: divided into hot-dip galvanized GB tube, galvanized coiled tube, and black tube after processing

After the completion of the greenhouse, whether the stress of the steel pipe is within the design range: If unexpected natural disasters such as blizzards and typhoons, the stress of the steel pipe will definitely exceed the design value and reduce the service life.

User's maintenance of Greenhouse Steel Galvanized Pipe: whether to add other objects on the steel pipe that exceed the load of the steel pipe, and whether the environment where the steel pipe is located is wet for a long time, etc.

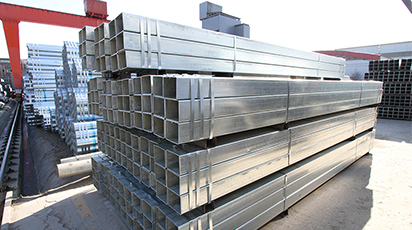

Greenhouse Steel Galvanized Pipe

What is the amount of galvanized steel pipe, more anti-corrosion effect of galvanized steel, long service life? In general, the service life of steel pipes of average quality is at least 10 years under normal use. The high-quality steel pipes of large brands are generally 15 to 20 years. The maintenance is good and the galvanizing amount is relatively large. It can even reach 30 years. Service life.

Factors affecting the quality of steel pipes:

The amount of galvanized steel pipe is extremely susceptible to air oxidation and rust, so anti-corrosion measures must be adopted. The most commonly used anti-corrosion measure is galvanizing on the surface of the steel pipe. The amount of galvanizing determines the corrosion resistance. The more galvanizing, The better the process, the better the quality of the steel pipe. But the more corresponding galvanizing, the higher the cost.

The wall thickness of the steel pipe, the steel pipe is a stressed member, which must be stressed. The thicker the wall of the steel pipe, the better the mechanical performance and the better the quality, but the thicker the wall, the higher the cost.

Process description of galvanized steel pipe

Hanging plating: also for hanging plating, with the best quality, the highest amount of zinc, and the strongest anticorrosion ability. Its technological process is roughly that the steel pipe is pickled. After the impurities above are washed away, the entire steel pipe is immersed in the zinc pool. The ascent cycle for more than ten seconds, take it out and cool it down. The amount of zinc on the steel pipe of the zinc-coating process reaches 400 to 600 grams, and the service life of the steel-plated steel pipe is 30 years. Nowadays, a large number of steel-plated steel pipes, high-speed rails, and infrastructure are used in the national major projects. Crafts, such as truss.

Blow plating: It also needs to be pickled and immersed in the zinc bath, but after lifting up, it will pass through a device. When the zinc is not completely attached to the steel pipe, the excess zinc is disposed of, but the amount of this zinc is slightly lower Now, the standard is about 200 grams, which is almost twice the amount of zinc on the zinc coating process. The cost of this kind of steel pipe is low, the service life can reach 15-20 years, and the cost performance is high. It is a common zinc plating process.

Galvanized belt: The steel material is plated in advance and then made into a pipe. The galvanized amount is low and the corrosion resistance is poor. The galvanized amount of 50 grams per square meter will rust in 2 to 3 years. It is not recommended in the greenhouse.

Cold plating: Since the country has high requirements for environmental protection, cold plating has gradually withdrawn from the stage of history. Nowadays, cold plating is basically not used anymore. It is an obsolete process.

Plastic coating: This process is a process to continue to increase the corrosion resistance after plastic coating on the galvanized pipe after the end of hot galvanizing, but the average cost per ton of steel will increase by about 2,000 yuan. The cost is too high and has not been used.

How to identify the quality of steel pipe with naked eyes

Hang plating: due to the thick zinc coating, the color is slightly darker than that of blow plating and tube;

Galvanized belt: The amount of zinc applied is low, the newly produced surface is bright, and it will show a little black after a period of time.