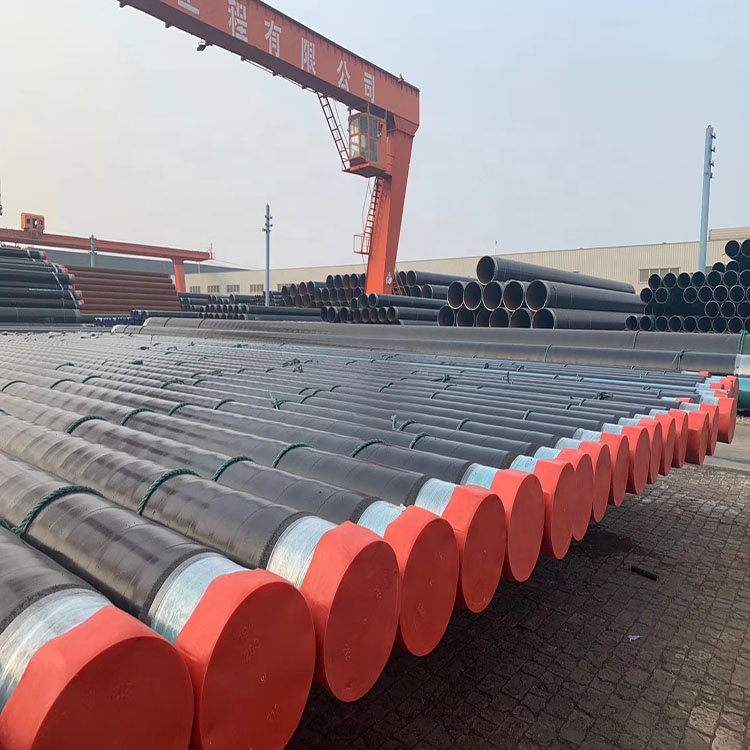

Seamless steel pipes, renowned for their strength and integrity, are cylindrical steel conduits devoid of any welding or seams. Commonly available in a variety of sizes, from small diameters of 10mm to larger ones of 300mm, with wall thicknesses ranging from 1mm to 50mm, they cater to diverse industrial requirements.

CREDIT

These pipes find extensive applications across sectors such as oil and gas, petrochemicals, construction, and automotive. Their superior resistance to pressure and corrosion makes them indispensable in high-stress environments, ensuring safe and efficient fluid transmission.

The advantages of seamless steel pipes are manifold. They offer enhanced durability, reduced risk of leaks, and a smoother internal surface, which minimizes friction and improves flow efficiency. Their seamless construction ensures a higher tolerance to internal pressure, making them ideal for critical applications.

CREDIT

Market trends indicate a growing demand for seamless steel pipes, driven by the expansion of infrastructure projects and the oil & gas sector. Innovations in manufacturing technologies are expected to further improve their performance and reduce production costs, making them more accessible and attractive to a broader range of industries.

Quality assurance is paramount in the production of seamless steel pipes. Stringent testing and inspection protocols, including hydrostatic testing and non-destructive examinations, ensure that each pipe meets or exceeds industry standards. This commitment to quality guarantees the reliability and longevity of seamless steel pipes in various applications, solidifying their position as a cornerstone in industrial construction and operations.