INTRODUCTION

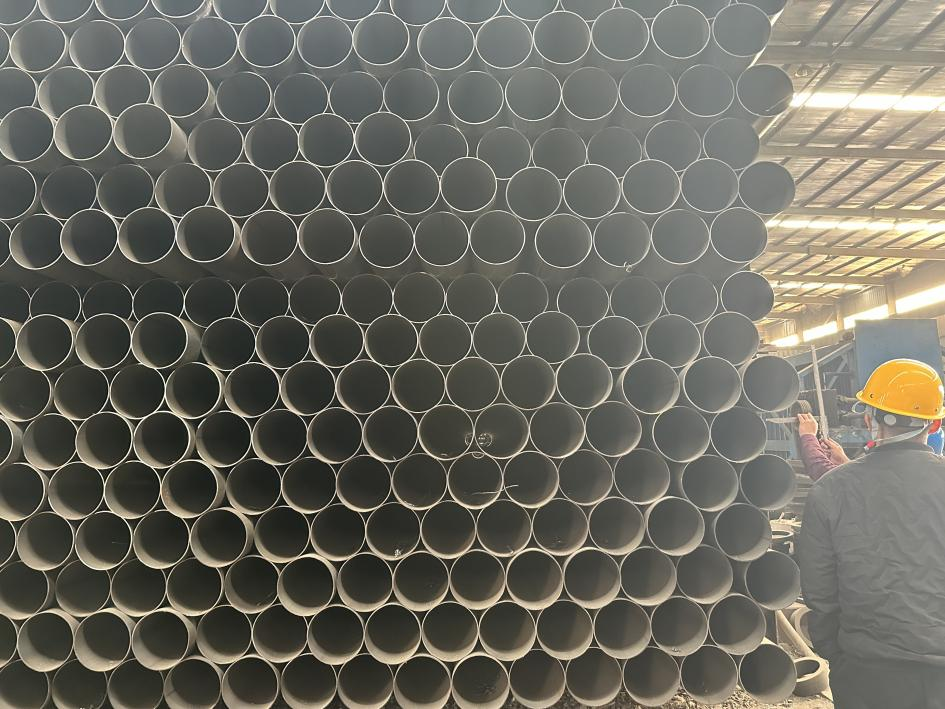

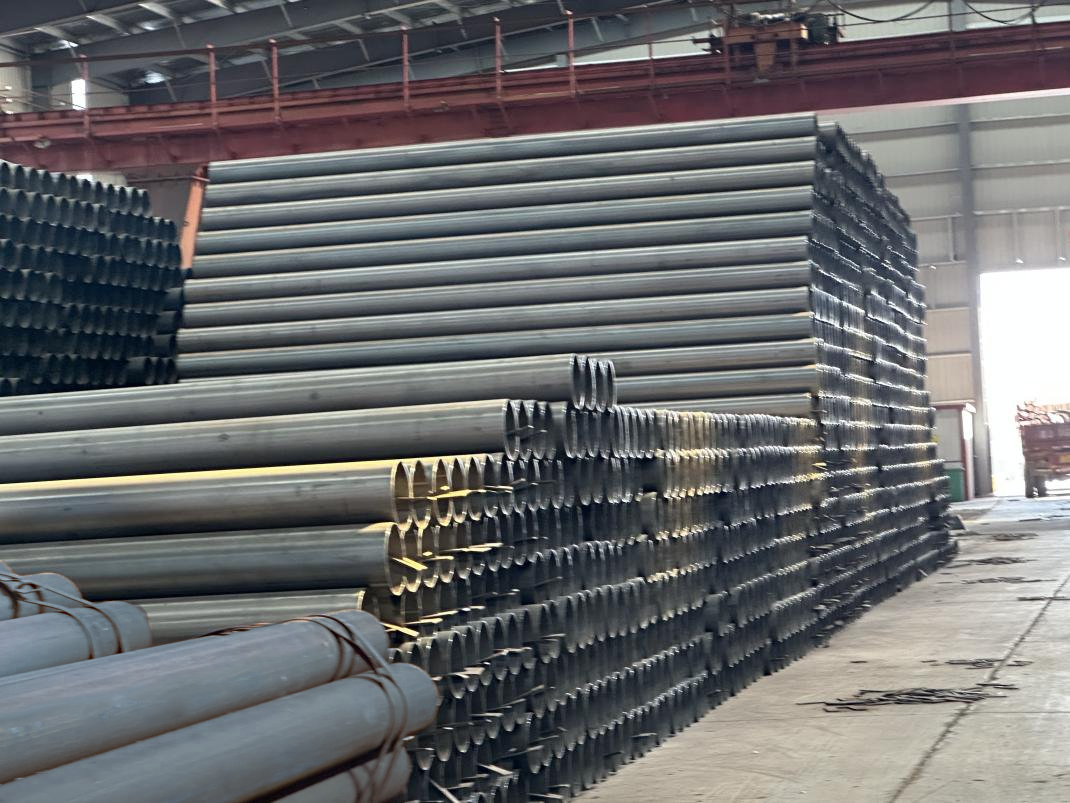

Longitudinal seam submerged-arc welded steel pipe, or LSAW pipe for short, is a type of pipe used in pipeline transportation. It is fabricated by welding a single steel plate using the submerged-arc welding process. This results in a pipe with a straight longitudinal weld seam.

APPLICATION

LSAW pipes are commonly used in medium to large diameter pipelines with a diameter of DN500 (500mm inner diameter) and above, especially in thick-walled pipes (above 20mm). They are widely applied in the following fields:

Oil and Gas Pipelines: Due to their ability to withstand high pressures and ensure fluid integrity, LSAW pipes are ideal for transporting oil and natural gas over long distances.

Building Structures: In recent years, LSAW pipes have been increasingly used in steel structures, such as bridges, dams, and offshore platforms, due to their excellent structural performance and cost-effectiveness.

Port and Marine Engineering: They are also used in port and marine equipment, showcasing their versatility and durability in harsh marine environments.

CREDIT

ADVANTAGES

High Strength and Pressure Resistance: LSAW pipes can withstand high internal and external pressures, ensuring safe and efficient fluid transportation.

Large Diameter and Thick Wall: They can be manufactured in large diameters and thick walls, making them suitable for a wide range of applications.

High Weld Quality: The submerged-arc welding process results in high-quality welds with a low defect rate.

Good Dimensional Accuracy: The pipes have good shape and accurate dimensions after full-length diameter expansion.

CREDIT

TREND AND PROSPECT

Increasing Demand: With the continuous development of infrastructure and industrial projects, the demand for LSAW pipes is expected to increase.

Technological Advancements: Advances in welding technology and manufacturing processes will further improve the quality and performance of LSAW pipes.

Broader Application Fields: As people's understanding of the structural advantages of LSAW pipes deepens, they are being applied to more fields, such as power station boilers and machinery manufacturing.

INSPECTION STANDARD

The inspection standards for LSAW pipes typically include:

GB/T 9711-2017: This is the Chinese national standard for steel pipes for pipeline transportation systems in the petroleum and natural gas industry.

API Spec 5L: This is an international standard for line pipe specification, widely used in the oil and gas industry.

These standards cover various aspects such as material composition, mechanical properties, weld quality, and dimensional accuracy to ensure the reliability and safety of LSAW pipes in various applications.

In summary, LSAW pipes offer a combination of strength, durability, and cost-effectiveness, making them an ideal choice for a wide range of applications. With technological advancements and increasing demand, their future prospects look promising.