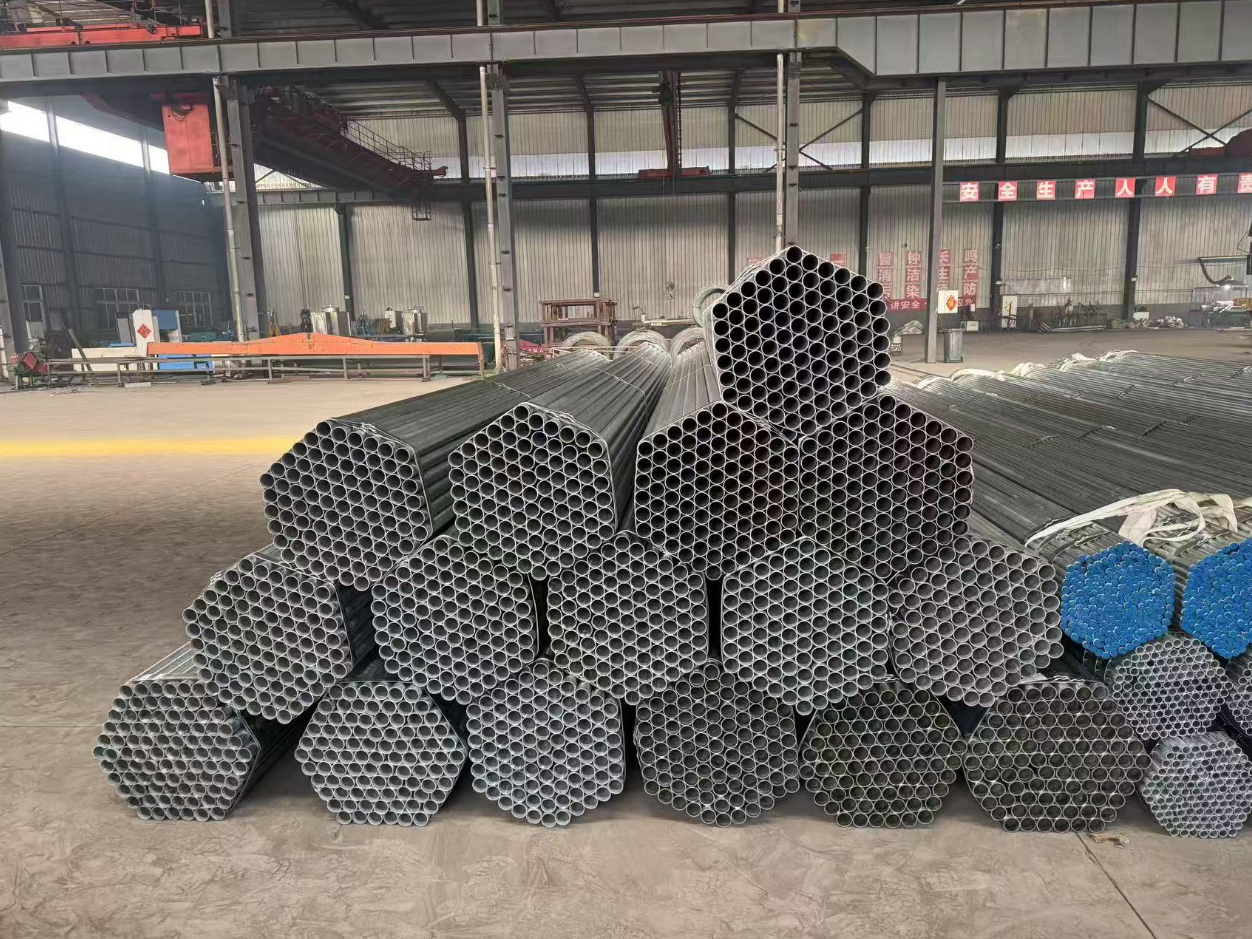

The performance of a hot-dip galvanized steel pipe is defined by the strength of the base steel and the long-lasting protection provided by the zinc coating. With exceptional resistance to corrosion, impact, and outdoor exposure, galvanized pipes remain one of the most dependable materials for modern engineering and infrastructure projects.

The zinc coating forms a dense, durable barrier that isolates the steel from moisture, oxygen, and corrosive chemicals. Even in humid, coastal, or industrial environments, galvanized pipes maintain structural integrity far longer than uncoated steel.

If the surface is scratched, zinc corrodes preferentially and protects the exposed steel. This self-healing effect ensures long-term durability, even under abrasion or rough handling.

Hot-dip galvanized pipes typically deliver decades of reliable performance with little or no maintenance, significantly reducing lifecycle costs for large-scale projects.

The metallurgical bond between zinc and steel enhances surface hardness, making the pipe more resistant to mechanical wear, weathering, and outdoor stress.

Galvanized pipes are suitable for welding, threading, cutting, and various forms of mechanical processing—ensuring flexibility for fabrication and field installation.

Used extensively in guardrails, outdoor structures, support columns, scaffolding, and protective barriers where long-term weather resistance is essential.

A preferred choice for municipal water lines, sprinkler systems, and low-pressure fluid transport due to their stable performance and corrosion resistance.

Ideal for greenhouses, irrigation lines, fencing, and livestock facilities, providing durability against moisture, fertilizers, and daily wear.

Used as conduits and protective casings for electrical wiring, solar mounting structures, and power transmission support systems.

Suitable for pipelines exposed to atmospheric corrosion, outdoor installations, and environments requiring stable long-term performance.