INTRODUCTION

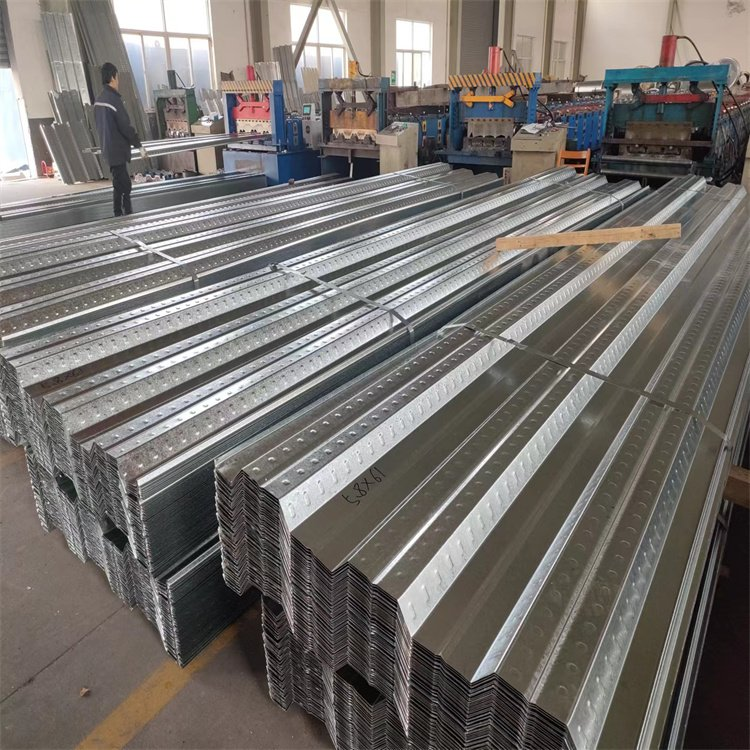

Galvanized steel roofing is a robust building material crafted from steel plates coated with a protective zinc layer through a galvanizing process. This combination harnesses the strength and stability of steel alongside the corrosion resistance of zinc, making it a versatile and durable choice for various building structures, particularly roofing.

Applications and Specifications

Galvanized roofing sheets are widely used as roof coverings due to their exceptional corrosion resistance, high strength, and long service life. They effectively prevent rainwater leakage while offering excellent heat insulation and thermal performance. These sheets are ideal for industrial plants, warehouses, agricultural greenhouses, and other structures requiring large-area coverage.

CREDIT

Specifications

Thickness: Typically ranges from 0.5 mm to 3 mm, catering to different load-bearing requirements.

Width and Length: Available in various dimensions to suit diverse building sizes and designs.

Customization: Can be tailored to specific needs, such as perforations or profiling, to meet unique project demands.

Advantages

Superior Corrosion Resistance: The zinc coating protects the steel from rust and oxidation, significantly extending the roof's lifespan.

High Strength: With excellent load-bearing capacity, galvanized roofing sheets can withstand harsh weather conditions and natural disasters.

Ease of Installation: Lightweight and easy to handle, these sheets reduce construction time and costs.

Aesthetic Appeal: The smooth surface and vibrant colors enhance the building's visual appeal while ensuring long-term durability.

Trends and Prospects

As the construction industry evolves and the demand for high-performance building materials grows, galvanized roofing sheets are poised for increased adoption. Their eco-friendly, energy-efficient, and sustainable properties align perfectly with the principles of green and energy-saving buildings. With ongoing technological advancements and product innovations, the application scope of galvanized roofing sheets is expected to expand further, offering a promising market outlook.

Inspection Standards

To ensure quality and performance, galvanized roofing sheets are subject to rigorous inspection standards:

Surface Quality: The sheets must have a smooth, defect-free surface, free from cracks, bubbles, or inclusions.

Zinc Coating Thickness: Measured to confirm compliance with industry standards.

Mechanical Properties: Evaluated through tensile and bending tests to assess strength, yield strength, and elongation.

Corrosion Resistance: Tested via methods like salt spray tests to verify durability under harsh conditions.

CREDIT