Product Introduction and Common Specifications

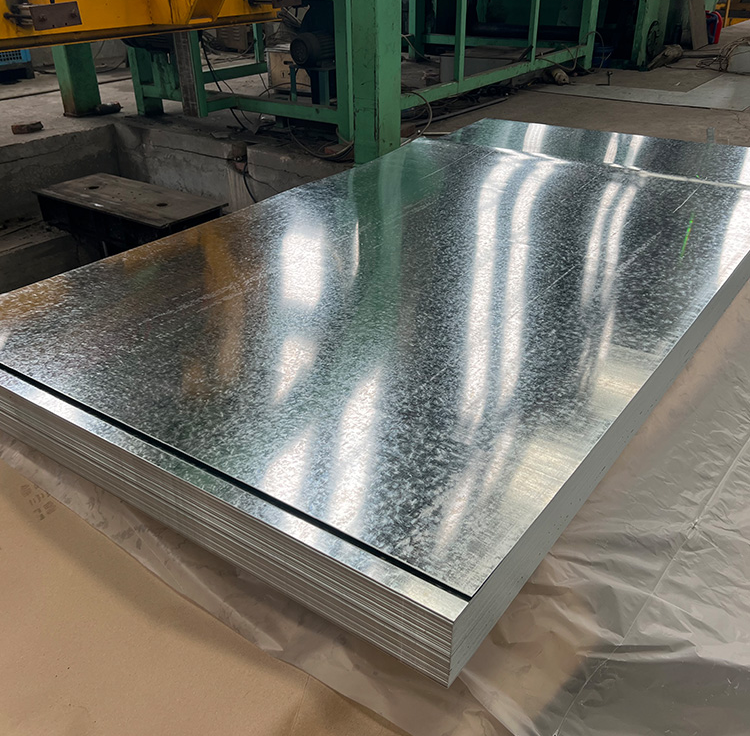

Galvanized sheet is a steel-based material coated with zinc to enhance corrosion resistance. This protective layer is applied through hot-dip galvanizing or electroplating, ensuring durability and longevity. Due to its excellent performance, galvanized sheet is widely used in construction, automotive manufacturing, and household appliances.

Typical specifications include thicknesses from 0.4mm to 3.0mm and standard widths of 1000mm, 1219mm, or 1250mm, with lengths customizable to meet specific requirements. The zinc coating thickness can also be tailored, with options such as Z60 or Z100 available to provide varying levels of corrosion protection based on the application environment.

CREDIT

Product Application and Advantages

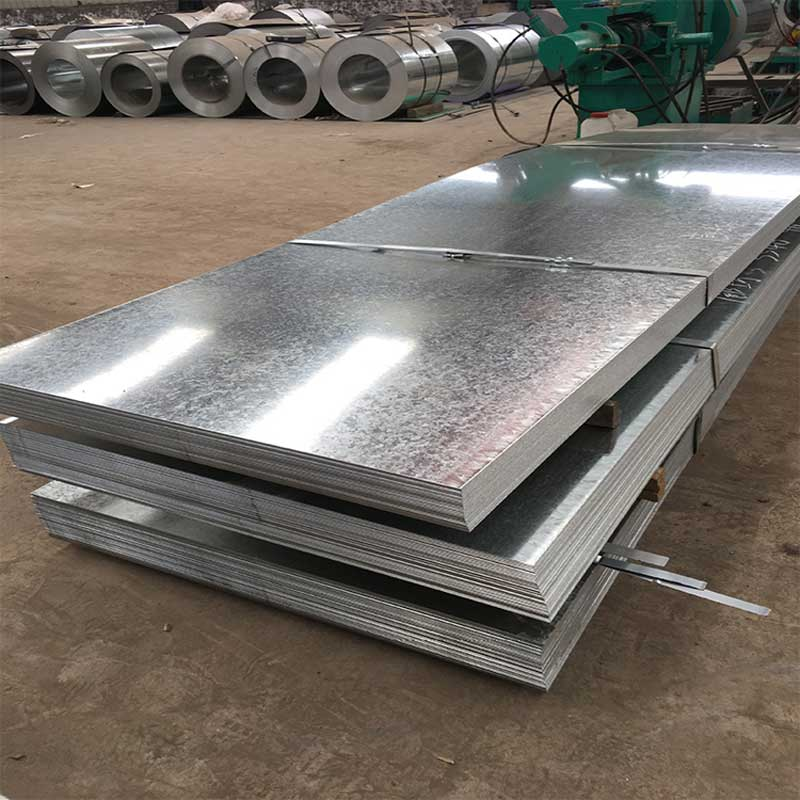

Galvanized sheets are widely used across multiple industries due to their durability and corrosion resistance. In construction, they serve as essential materials for roofs, walls, and fences. The automotive industry utilizes galvanized sheets to protect body panels and chassis from rust and environmental damage. In the home appliance sector, they are commonly used for the outer casings of products such as refrigerators and washing machines. Additionally, galvanized sheets play a crucial role in the production of protective structural components for mechanical equipment.

The benefits of galvanized sheets are numerous. Their zinc coating provides excellent corrosion resistance, preventing oxidation and significantly extending their lifespan. They are both strong and lightweight, making them easy to process, transport, and install. Their smooth and aesthetically pleasing surface also makes them suitable for decorative applications. Furthermore, galvanized sheets are fully recyclable, supporting modern environmental sustainability initiatives.

CREDIT

Product quality inspection methods

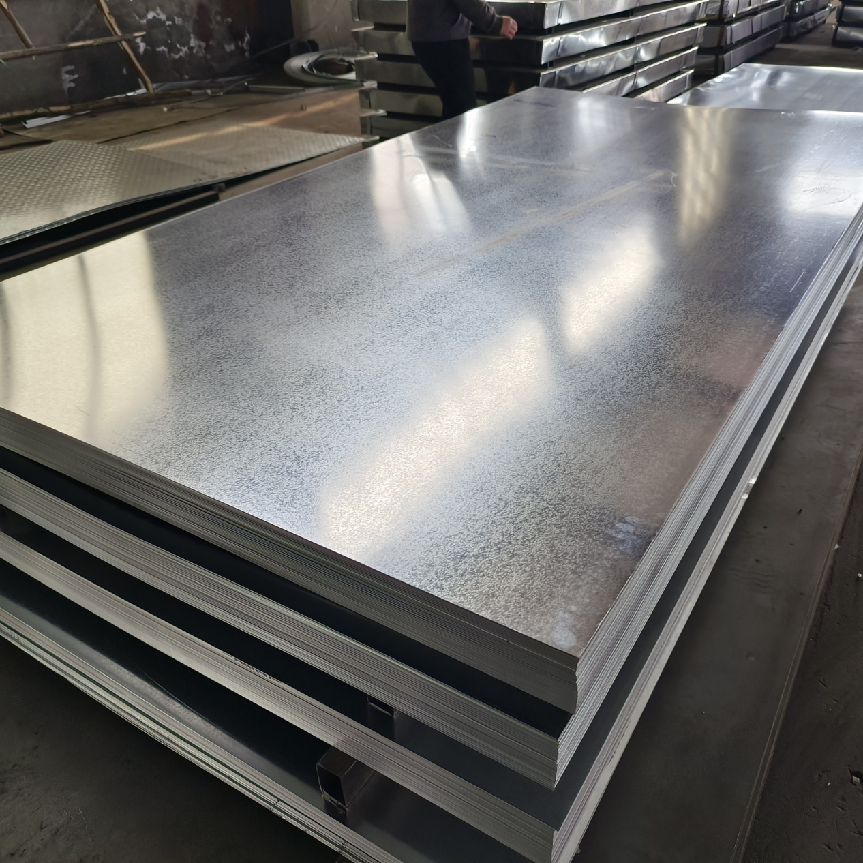

To guarantee the quality of galvanized sheets, rigorous inspection procedures are essential. First, raw materials undergo thorough testing to ensure that both the base steel and zinc coating comply with national standards. During production, the galvanizing process is continuously monitored in real-time to maintain uniform zinc layer distribution.

Once production is complete, finished products are inspected based on key criteria, including thickness, zinc layer adhesion, and surface appearance. Finally, random sampling is conducted before shipment to verify compliance with factory quality standards, ensuring that only high-quality products reach the market.

Steel Roofing Sheets

Market development trends

With the continuous growth of the construction, automotive, and home appliance industries, the demand for galvanized sheets is steadily increasing. Looking ahead, the galvanized sheet market is expected to follow several key trends.

First, environmental regulations will become more stringent, driving the development of products that align with green building standards. Second, the adoption of intelligent manufacturing technologies will accelerate, enhancing production efficiency and product quality. Third, the demand for customized solutions will continue to rise, as the market increasingly prioritizes personalized services to meet diverse customer needs.