Product Introduction and Common Specifications

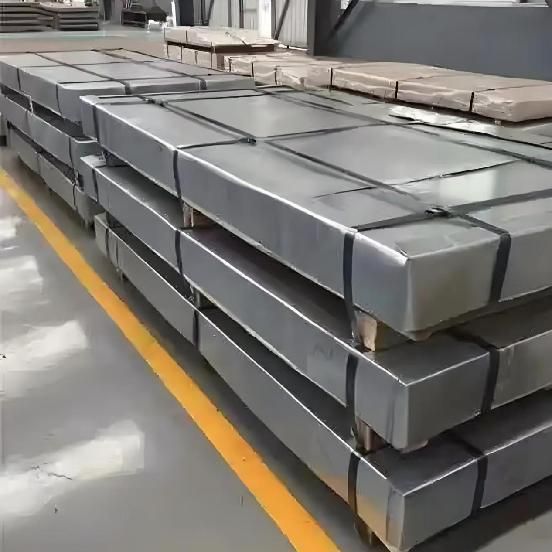

Galvanized sheet is a material that combines the strength of steel with the corrosion-resistant properties of zinc. This is achieved by coating the steel surface with a zinc layer through hot-dip galvanizing or electroplating. Due to its excellent durability, it is widely used in industries like construction, automotive, and home appliances.

Common specifications for galvanized sheets include thicknesses from 0.4mm to 3.0mm, with widths typically at 1000mm, 1219mm, or 1250mm. The length can be customized based on customer requirements. Additionally, the thickness of the zinc layer can be selected to meet specific corrosion resistance needs, such as Z60 or Z100, depending on the environment of use.

Product Application and Advantages

Galvanized sheets have a broad range of applications across various industries. In construction, they are commonly used for structures like roofs, walls, and fences. In the automotive sector, galvanized sheets are an ideal choice for protecting body parts and chassis from corrosion. The home appliance industry also frequently uses galvanized sheets for the outer casings of products like refrigerators and washing machines. Additionally, galvanized sheets are widely utilized in protective structural components for mechanical equipment.

The advantages of galvanized sheets are numerous. They offer excellent anti-corrosion properties, as the zinc coating effectively prevents oxidation and extends the material's lifespan. Galvanized sheets are both strong and lightweight, making them easy to process, handle, and transport. Their smooth, attractive surface also makes them ideal for decorative applications. Moreover, galvanized sheets are recyclable, aligning with modern environmental sustainability standards.

CREDIT

Product quality inspection methods

In order to ensure the quality of galvanized sheets, strict quality inspection procedures are indispensable. First, the raw materials are inspected to ensure that the base material and zinc layer meet national standards. Secondly, the galvanizing process is monitored in real time during the production process to ensure the uniformity of the zinc layer. Finished product inspection includes multiple indicators such as thickness, zinc layer adhesion and appearance. Finally, random sampling is carried out for factory inspection to ensure that the product meets factory standards.

Steel Roofing Sheets

Market development trends

As the construction, automotive and appliance industries continue to grow, demand for galvanized sheets is rising steadily. In the future, the galvanized sheet market will show the following trends: first, environmental protection requirements will continue to increase, and future products will be more likely to comply with green building standards; second, intelligent manufacturing will gradually become popular to improve production efficiency and product quality; third, The demand for customization is growing, and the market demand for personalized services is also rising.

CREDIT