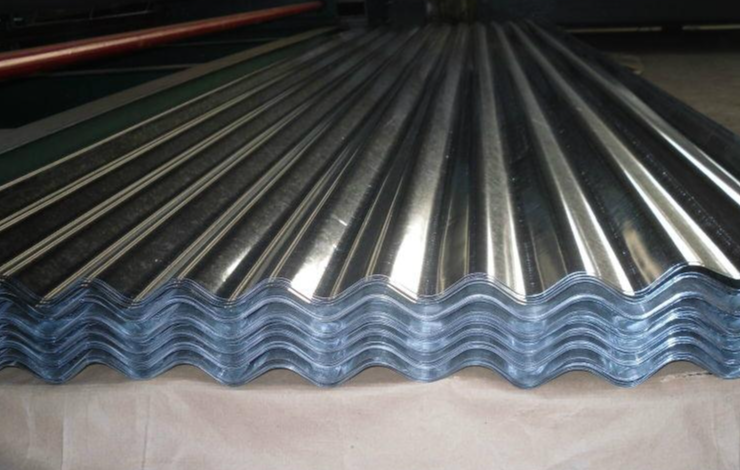

Galvanized roofing sheets are a popular choice in construction due to their durability, affordability, and resistance to environmental factors. These sheets are made from steel coated with a layer of zinc through a process called galvanization, which significantly enhances their lifespan and performance.

Manufacturing Process

The production of galvanized roofing sheets involves immersing cleaned steel sheets into molten zinc at high temperatures (typically around 450°C). This process, known as hot-dip galvanization, creates a metallurgical bond between the zinc and steel. The zinc coating acts as a sacrificial layer, corroding before the underlying steel, thereby preventing rust. Depending on requirements, the zinc coating thickness can vary, with higher coatings offering extended protection. Some variants may include additional treatments, such as paint or polymer coatings, for enhanced aesthetics or performance.

CREDIT

Key Advantages

1. Corrosion Resistance: The zinc coating provides exceptional protection against rust, making these sheets ideal for humid, coastal, or industrial areas.

2. Longevity: Properly galvanized sheets can last 20–50 years, reducing replacement costs.

3. Cost-Effectiveness: They are more affordable than materials like aluminum or copper while offering comparable strength.

4. Strength and Lightweight: Steel sheets maintain structural integrity under heavy loads, yet are easy to transport and install.

5. Low Maintenance: Minimal upkeep is required beyond occasional cleaning to remove debris or pollutants.

Applications

Galvanized roofing sheets are widely used in industrial warehouses, agricultural buildings, residential homes, and commercial structures. Their versatility extends to applications like wall cladding, gutters, and rainwater systems. In agriculture, they are favored for barns and storage sheds due to their ability to withstand harsh weather and chemical exposure.

Environmental Considerations

Galvanized steel is 100% recyclable, aligning with sustainable construction practices. The energy-efficient production process and long service life further reduce its environmental footprint.

Installation Tips

To maximize performance, ensure proper overlap between sheets and use corrosion-resistant fasteners. Adequate ventilation and slope design help prevent water pooling, which can degrade the coating over time.