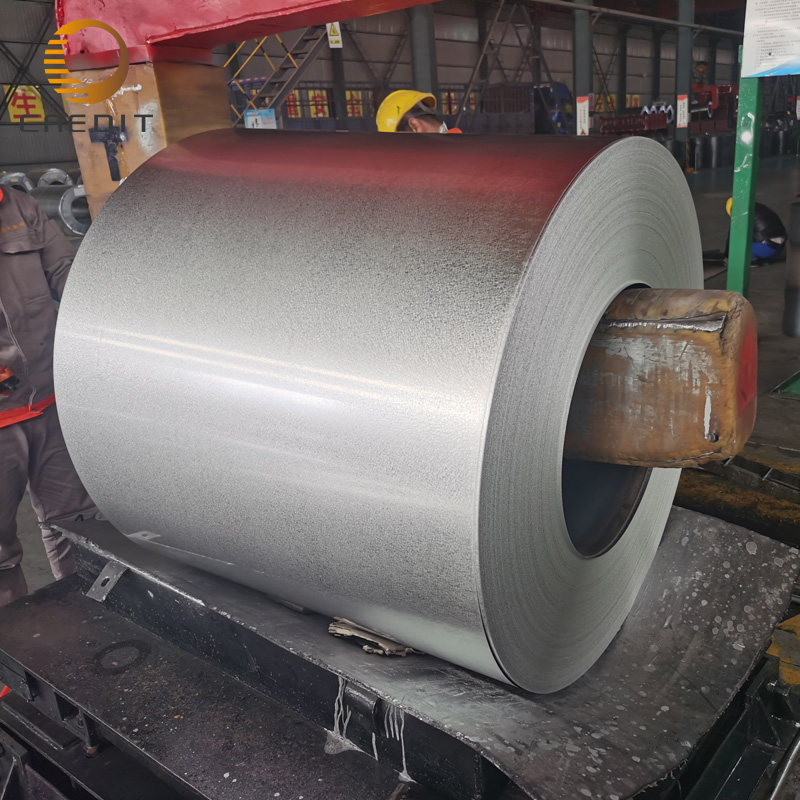

EGI (Electro-Galvanized Iron) sheets, also known as electro-galvanized steel sheets, are cold-rolled steel sheets coated with a thin layer of zinc through an electrolytic process. This coating enhances corrosion resistance, improves aesthetics, and provides better paint adhesion. EGI sheets are widely used in industries requiring high surface quality and durability.

Common Dimensions

EGI sheets are available in a range of thicknesses, typically from 0.12 mm to 4.75 mm. Standard widths vary between 900 mm and 3,500 mm, while lengths can range from 1,000 mm to 6,000 mm. Specific dimensions may vary based on manufacturer specifications and customer requirements. For specialized applications, custom sizes (e.g., smaller panels like 500 × 500 mm or 600 × 600 mm) can be produced.

Primary Applications

EGI sheets are valued for their excellent formability, surface quality, and corrosion resistance. Key industries and applications include:

1. Construction: Used for roofing, wall panels, and structural components due to their durability and resistance to environmental damage.

2. Automotive: Employed in vehicle bodies and parts where lightweight, high-strength, and corrosion-resistant materials are critical.

3. Appliances: Widely used in household appliances (e.g., washing machines, refrigerators) where a smooth, paintable surface is essential.

4. Electronics: Utilized for casings and components requiring precise dimensions and a clean surface finish.

Market Conditions

The global market for EGI sheets is competitive, with significant production and consumption in Asia. Key insights include:

Production Trends: Countries like India have seen steady growth in EGI production, with annual output reaching approximately 800,000–900,000 tons in 2023, driven by demand from construction, automotive, and appliance sectors.

Profitability Challenges: Despite demand, profitability for manufacturers (e.g., in South Korea) has been pressured due to sluggish demand, low export prices, and reduced operational efficiency. For instance, profit margins for South Korean producers like POSCO dropped to around 11% for EGI products in some periods.

Regional Demand: Infrastructure projects (e.g., India’s "Smart City" initiatives) and automotive industry growth continue to drive demand. However, factors like raw material price volatility, environmental regulations, and international trade policies pose challenges.

Innovation and Sustainability: Manufacturers are adopting eco-friendly production processes and developing higher-quality coatings (e.g., zinc coatings ranging from 50 to 150 g/m²) to meet stricter environmental standards and diverse application needs.

Conclusion

EGI sheets are versatile materials critical to multiple industries, offering a blend of corrosion resistance, formability, and surface quality. While market demand remains robust, particularly in emerging economies, manufacturers face challenges related to profitability and regulatory compliance. Innovations in coating technologies and sustainable production methods are expected to shape the future of the EGI market.

Previous: Welded steel pipes

Next: Galvanized steel coils