Product Introduction and Common Specifications

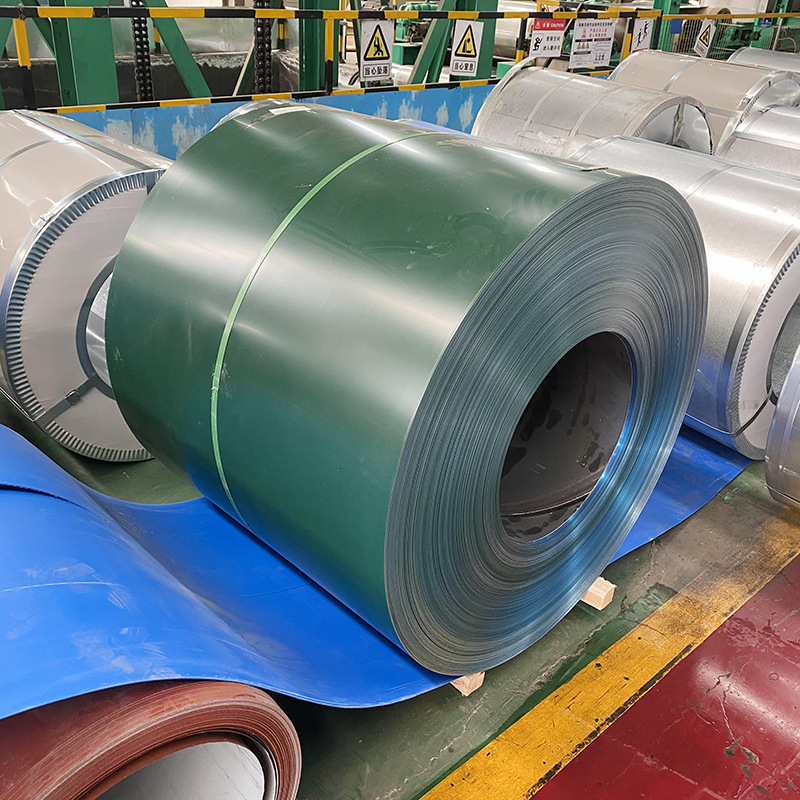

Color-coated steel coils, also known as pre-painted steel coils, are produced by applying an organic coating to galvanized or galvalume steel substrates, followed by a high-temperature curing process. This results in a product that not only retains the strength and durability of the underlying metal but also offers a wide selection of colors and enhanced surface protection. Due to these advantages, color-coated coils are widely used across various industries including construction, home appliances, and transportation, making them an ideal material for modern architecture and industrial applications.

Standard specifications for color-coated coils typically include thicknesses ranging from 0.2 mm to 1.5 mm, widths between 600 mm and 1250 mm, and a variety of coating systems to suit specific requirements. Common coating types include polyester (PE), silicon-modified polyester (SMP), high-durability polyester (HDP), and polyvinylidene fluoride (PVDF), each offering different levels of weather resistance, gloss retention, and flexibility to meet diverse customer needs.

CREDIT

Product Application and Advantages

Color-coated steel coils are widely applied across a diverse range of industries due to their versatility and performance. In the construction sector, they are frequently used for roofing, wall cladding, roller shutters, and window blinds. Within the home appliance industry, they serve as exterior components for refrigerators, washing machines, and air conditioners. In the transportation field, these coils are employed in the manufacturing of containers and both interior and exterior automotive trim. Additionally, color-coated coils are well-suited for decorative and protective applications in environments such as cold storage facilities, garages, and thermal insulation systems.

The key advantages of color-coated coils lie in their aesthetic appeal, weather resistance, corrosion protection, and environmental performance. With a wide array of colors and surface patterns, they offer great flexibility for architectural and industrial design. Their excellent UV resistance and anti-aging properties make them highly durable in harsh outdoor environments, significantly extending their service life. Leveraging advanced coating technologies, these coils exhibit superior corrosion resistance, comply with environmental protection standards, and contribute to energy efficiency by minimizing heat loss.

Hot-Dip Galvanized Sheet

Product quality inspection methods

To ensure the consistent quality of color-coated steel coils, the entire production process must undergo a rigorous and comprehensive quality control system. At the raw material stage, both the steel substrate and the coating formulations are thoroughly tested to verify compliance with national and industry standards. During production, real-time monitoring is employed to control critical parameters such as coating thickness, adhesion strength, and surface gloss, ensuring uniform application and optimal product performance.

Upon completion, finished product inspections are conducted, including simulated environmental tests such as salt spray resistance, corrosion resistance, and impact durability, to verify that the coils can perform reliably under various service conditions. This multi-level quality assurance process guarantees that color-coated coils meet the high standards required by the market and deliver consistent performance across a wide range of applications.

Market development trends

As demand grows for materials that are not only aesthetically appealing but also durable and environmentally sustainable, color-coated steel coils are evolving to meet higher performance standards and embrace smart technologies. Looking ahead, the market is expected to see increased demand for coils with enhanced weather resistance, eco-friendly coatings, and innovative functionalities, such as intelligent color-shifting capabilities. These advancements will not only enhance product competitiveness but also accelerate technological progress within the industry.

Furthermore, as consumer preferences increasingly favor personalization and customization, the range of colors, finishes, and surface textures available in color-coated coils will continue to expand. This trend will enable manufacturers to better meet the diverse aesthetic and functional requirements of modern construction and industrial applications.