The spiral steel pipe water delivery irrigation system can be divided into mobile, semi-fixed, and fixed according to the working model.

1. Mobile. In addition to the water source, pipes and water distribution equipment can be moved, some pumps are fixed, and some can also be moved. Spiral steel pipes mostly use thin-film plastic hoses (small white dragons) or vinyl coated plastic hoses, which are simple and easy to operate, low in cost, flexible in use, strong in adaptability, and capable of turning at will across trenches. But the film plastic hose is not durable and easy to break, and life is generally only 1-2 years. In the late growth stage of high-stalk crops, it is difficult to move the hose in the ridge between rows because the crop grows tall.

2. Part of the semi-fixed piping system is fixed and the other part moves. Generally, the main pipe or trunk and branch pipes are fixed buried pipes, and the mobile hose is connected to the field by the water diversion port. In this form, the distance between branch pipes is large, and the distance between water outlets is also large. Accordingly, the amount of fixed buried pipes is reduced, and the investment per unit area is reduced.

3. Fixed type. All pipelines and water distribution facilities in the low-pressure pipeline water delivery irrigation system are buried underground and are fixed. The water supply plug or the water distribution port directly divides the water into the field furrow without a hose connection. The furrows in the field are short, the density of the fixed spiral steel pipe is high, and the standard is high. This type of system is easy to operate and manage, with even irrigation, but the one-time investment is correspondingly large.

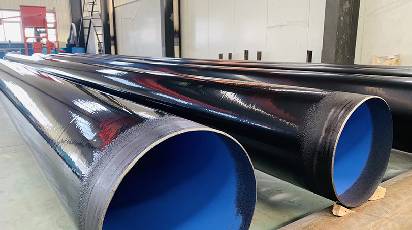

Spiral Steel Pipe

Longitudinal submerged arc welded steel pipe welding position is located on the slope, the weld metal in the molten state will produce lateral flow under the action of gravity (that is, to the free side of the forming seam), which is easy to cause the weld to drift, Causing the weld to deviate. It is very easy to produce welding hot cracks. The direction of the cracks is parallel to the welding seam and forms a certain angle with the axis of the steel pipe. It is generally between 30-70 °. This angle is just consistent with the shear failure angle, so its bending and tensile strength, Compression, and torsion performance are far inferior to straight-seam submerged arc welded pipe, at the same time due to the welding position are limited, the resulting saddle-shaped and ridge-shaped welds affect the appearance.

Oil pipeline spiral steel pipe is one of the important parts of the petroleum and pipeline construction business. It's flexible and convenient, lightweight, and low-cost characteristics have attracted more and more attention from the industry. During the whole welding process of spiral submerged arc welded steel pipe, due to the horizontal crosstalk of the steel plate, the adjustment of the angle, and the accuracy of the equipment used, a certain deviation between the welding distance and the weld seam is often caused, which leads The quality of the produced steel pipe has problems. Therefore, in order to improve the welding quality and reduce the deviation between the welding distance and the welding seam, it is necessary to develop the automatic tracking technology of the spiral seam submerged arc welding seam.

It is then fed into a hot-dip galvanizing tank. Hot-dip galvanizing has the advantages of uniform coating, strong adhesion, and long service life. The complex physical and chemical reactions between the steel pipe substrate and the molten plating solution form a corrosion-resistant, compact zinc The iron alloy layer, the alloy layer, and the pure zinc layer, and the steel pipe matrix are integrated, so its corrosion resistance is strong.