Product Introduction and Common Specifications

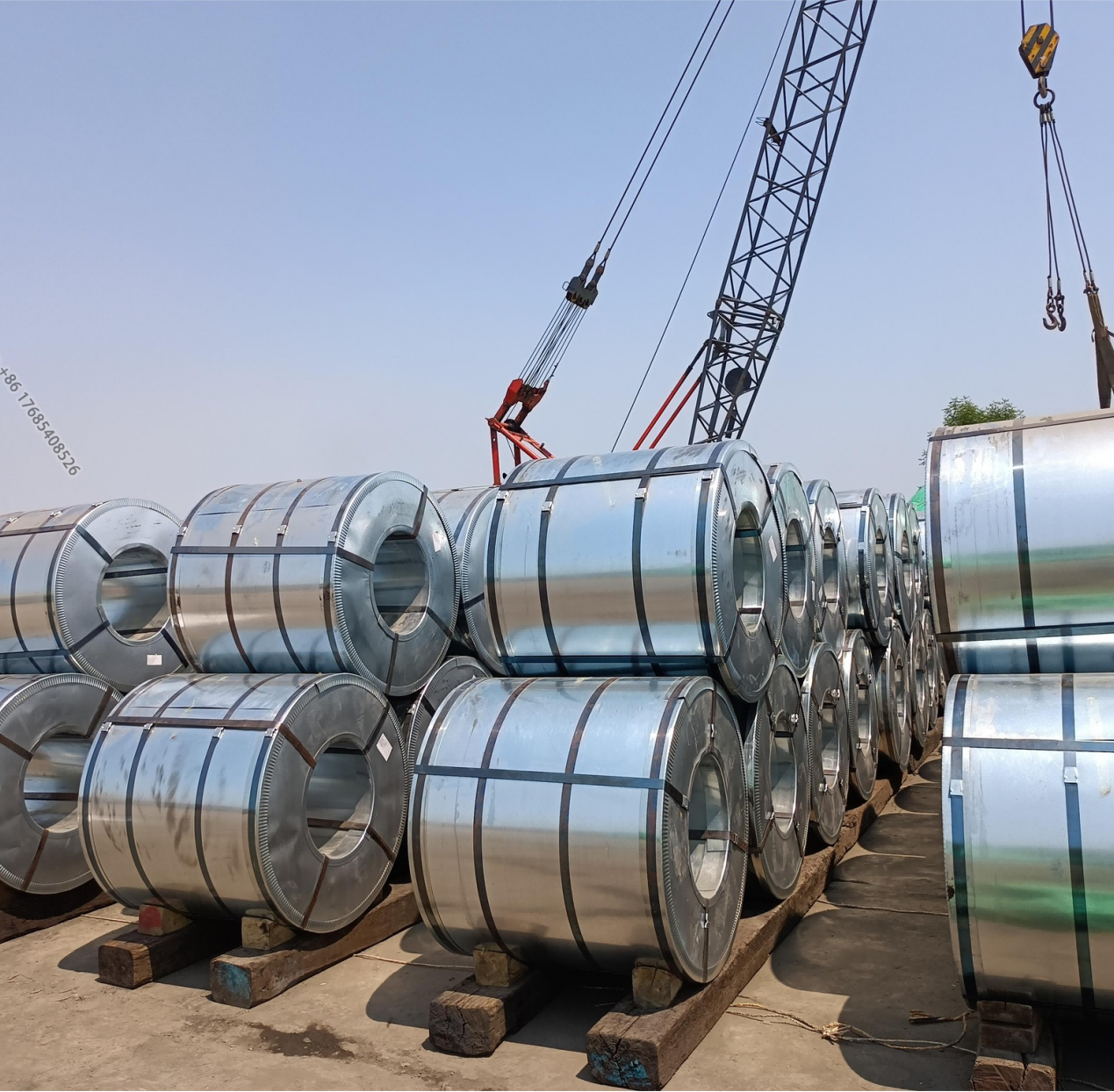

Al-Zn coated steel coil is a steel product featuring a surface coating of aluminum-zinc alloy, which forms a uniform, highly corrosion-resistant protective layer. This material offers superior performance in terms of corrosion resistance, heat resistance, and weather durability compared to conventional galvanized steel, making it ideal for use in demanding environments. It is widely applied across various industries, including construction, automotive, and home appliances.

Typical specifications of Al-Zn coated steel coil include a thickness range of 0.14mm to 2.0mm, widths from 600mm to 1500mm, and coating weights between 30g/m² and 300g/m².

Product Application and Advantages

Al-Zn coated steel coils can be customized with various surface treatments—such as mirror finish, matte texture, or color coating—to meet the specific requirements of different applications. These coils are most widely used in the construction industry for corrosion-resistant roofing, wall cladding, and gutter systems. In the home appliance sector, they serve as protective casings for electrical components, while in the automotive industry, they are utilized for anti-corrosion body panels and chassis parts. The energy sector also benefits from Al-Zn coils, particularly in the production of solar panel back sheets and energy storage enclosures.

Thanks to their superior resistance to high temperatures and UV radiation, Al-Zn coated coils are also commonly used in pipelines, metal furniture, and other demanding applications. Their advantages lie in exceptional corrosion resistance, thermal stability, weatherability, and ease of fabrication. The aluminum-zinc alloy coating offers dual-layer protection, significantly extending the product’s lifespan compared to traditional galvanized materials—especially in harsh outdoor environments.

Moreover, Al-Zn coils are highly workable, supporting various processing techniques such as cutting, bending, and welding, making them suitable for diverse manufacturing needs. Environmentally friendly and compliant with sustainable development standards, these products are increasingly adopted in green building projects and eco-conscious industrial applications.

Pre-painted Galvalume Coil

Product quality inspection methods

The quality inspection process for galvanized coils involves rigorous controls throughout the entire production cycle to ensure product reliability and performance. Initially, the raw materials undergo testing for chemical composition and mechanical properties to confirm compliance with production standards.

Subsequently, specialized equipment is used to measure the thickness and uniformity of the aluminum-zinc coating, ensuring consistent coverage across every coil. Surface inspections are also conducted meticulously to detect and eliminate defects such as cracks, bubbles, or scratches.

Key mechanical performance evaluations—including tensile strength and bending tests—are carried out alongside corrosion resistance assessments such as salt spray testing. These steps are critical in verifying the coil’s durability and suitability for various applications.

Before delivery, all finished products are carefully packaged and undergo final inspections to confirm they meet transport and handling standards.

CREDIT

Aluminum Zinc Roofing Sheet

Market development trends

With the increasing demand for high-performance and environmentally sustainable materials, galvanized coils are poised for strong market growth. In particular, the rise of green building initiatives and the development of lightweight vehicles are driving sustained demand for this versatile material.

Looking ahead, ongoing technological advancements will continue to improve both the production processes and performance characteristics of galvanized coils. Innovations in coating technology are expected to further enhance product durability, efficiency, and market competitiveness.

Moreover, as industrialization accelerates across Asia and other emerging markets, global demand for galvanized coils is set to expand significantly. These trends position galvanized coils as a vital and irreplaceable material in the global manufacturing landscape.