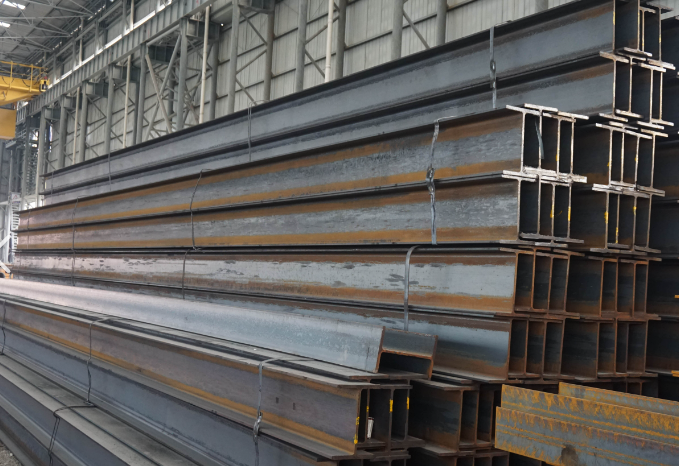

An H-beam, also known as an H-shaped steel or wide flange beam, is a structural steel profile characterized by its distinctive "H" cross-sectional shape. It consists of two horizontal flanges (top and bottom) connected by a vertical web, forming a highly efficient load-bearing structure. H-beams are widely used in construction and engineering due to their excellent strength-to-weight ratio and versatility.

Cross-Sectional Design:

The web (central vertical section) resists shear forces, while the flanges (horizontal sections) withstand bending moments.

The symmetrical H-shape provides uniform strength in multiple directions.

Material:

Typically made of rolled steel, with common grades including ASTM A36, S235, S355, or high-strength low-alloy (HSLA) steel.

Advantages:

High Load Capacity: Ideal for supporting heavy loads in beams, columns, and frameworks.

Lightweight: Offers greater strength with less material compared to solid sections.

Ease of Fabrication: Can be welded, bolted, or cut to fit specific project requirements.

Economic Efficiency: Reduces construction time and material costs.

Manufacturing Methods:

Hot-Rolled: Produced by heating steel billets and shaping them through rollers.

Welded: Fabricated by welding steel plates for customized dimensions.

Construction: Building frames, bridges, and industrial structures.

Infrastructure: Support columns, roof trusses, and crane rails.

Recyclability: Steel H-beams are 100% recyclable, reducing environmental impact.

High-Strength Steel: Grades like S460 or ASTM A913 allow lighter, stronger designs.

Hybrid Beams: Combining steel H-beams with composite materials (e.g., concrete-filled tubes).

Digital Fabrication: BIM (Building Information Modeling) and CNC machines optimize cutting/welding precision.

CREDIT

Fire Resistance: Intumescent coatings or concrete encasement for fire-rated structures.

Connection Design: Bolted vs. welded joints; moment connections vs. shear connections.

Used hybrid steel-concrete H-beams for the world’s tallest bridge piers.

Optimized for wind resistance and minimal material usage.

Corrosion: Requires protective coatings in humid or marine environments.

Weight: Despite efficiency, large H-beams need cranes for installation.

Cost: Custom sizes (welded beams) are more expensive than standard rolled sections.