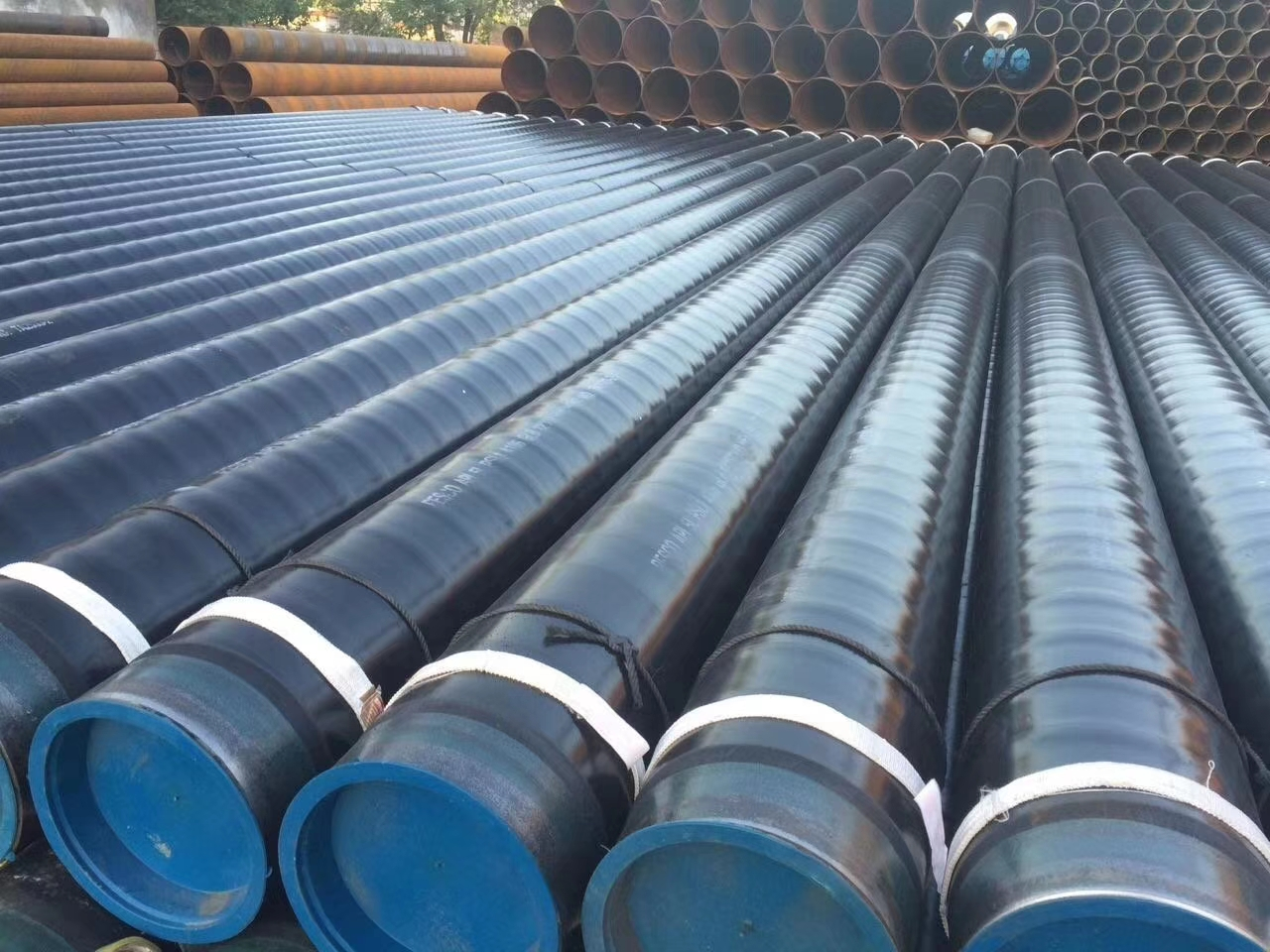

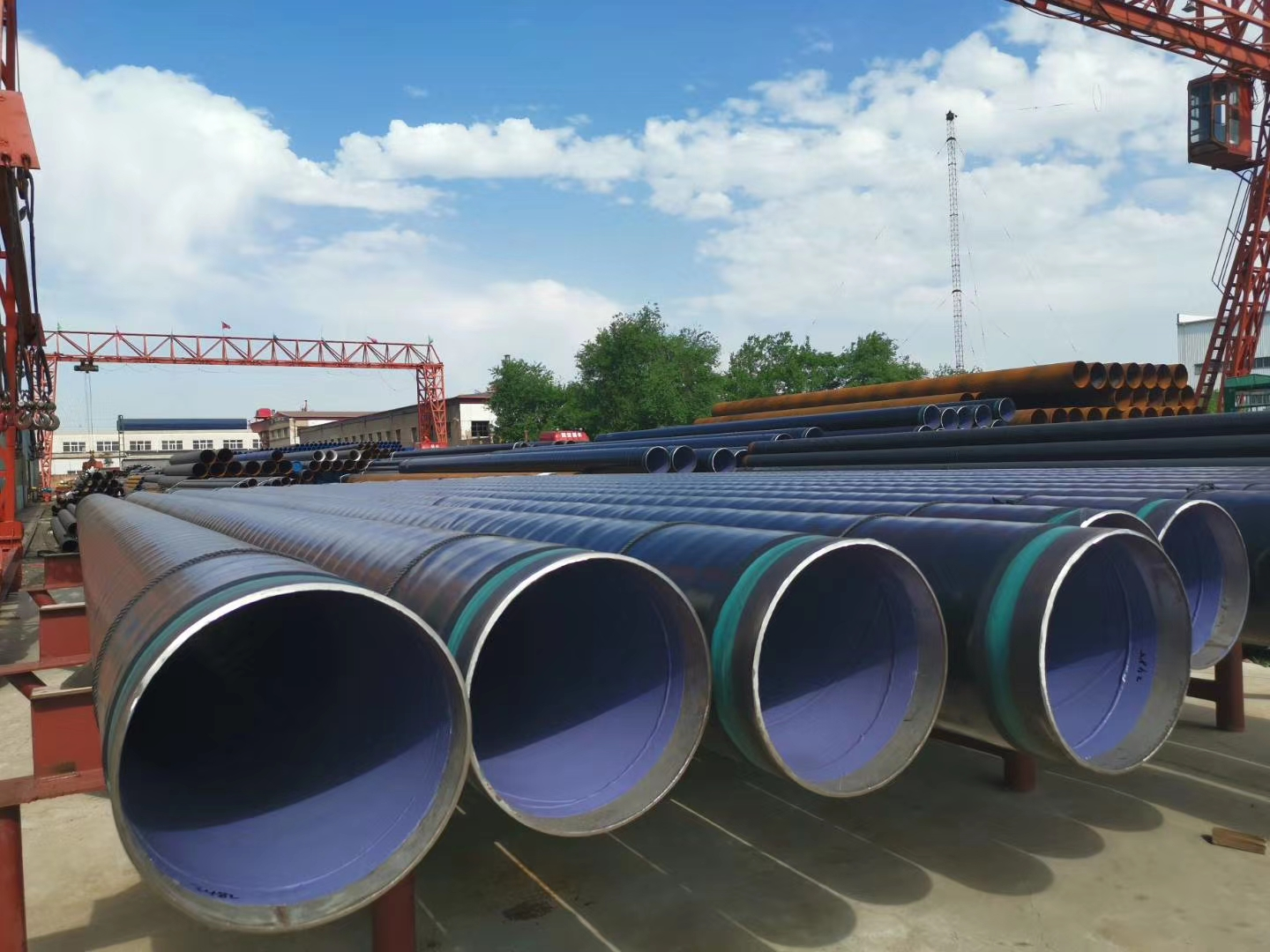

3LPE coated steel pipe also called as 3PE is one kind of coating method which used in carbon steel pipe. No matter which pipe it is, whether it is seamless steel pipe, welded steel pipe, stainless steel pipe or alloy steel pipe, it can do 3LPE coating for the pipes. The Common use of 3LPE coated steel pipe is in the pipeline Industry. As carbon steel pipe is widely used in pipeline systems for transportation of oil, gas, water and other fluids.

Standard: DIN 30670-2012,CAN/ CSA Z245.21, ISO 21809-1,NFA 49-710, Shell DEP 31.4030.31-CSPC

Pipe sizes: 60.3-1422.4mm (NPS 2’’ TO NPS 56’’)

Minimum coating thickness ≥ 2.5mm

Length ≥ 5.8m

l Layer 1: The First layer is of fusion bonded epoxy, which protects pipe from corrosion when needed.

l Layer 2: Layer of Copolymer Adhesive who has a natural bonding with the inner layer and the top

l Layer 3: Polyethylene Coating which helps the pipe to avoid any physical damage

3LPE Coated pipes used for transmission of oil and gas as it can withstand a temperature higher than the other pipes. It can withstand varied temperatures from dry land desserts to underwater pressures, hot temperatures to cold winters. The 3-layer coating help withstand all weather conditions and polyethylene coating helps withstand physical damage.

Coating application:

Pipe surface preparation by sand blast cleaning(SSPC-SP10)NACE No.2/ISO 8501-1 Sa 2 1/2/SIS 05 59 00)

After the pipe is heated and melted, it should be coated with epoxy powder.

The extruded adhesive should be applied to the pipe.

Finally, a layer of extruded polyethylene should be applied over the adhesive layer.

Total coating thickness is typically <3.0mm for pipes <24’’ diameter and 3.3mm for pipes 32’’ diameter and larger.

CREDIT

Advantages of 3LPE Coating Pipes

· Durable Lifetime

3LPE coated steel pipe has a service life for above 50 years. It is because 3LPE coating has good stability and anti-aging performances, which works under normal temperature and pressure conditions.

· Corrosion Resistance

The elements of PE structure stability are high. So, we can use it to prevent corrosion from natural gas, liquefied petroleum gas, artificial gas, and other chemical subjects. And it needs no secondary anti-corrosion equipment. The chemical of soil does not produce any effects on the steel pipe using 3LPE coating.

· Flexibility

3LPE coating is a kind of soft and flexible material, it breaks after prolong 5 times longer. It is easy to bend without damage. 3PE coating steel pipe can bypass steel pipe and reduce the fees of installation.

· Safe and reliable connection way

3LPE coating steel pipe mainly uses hot melt and fused connection, which connects the interface and pipeline as a whole. There is no water and gas leakage in this coated steel pipe.

CREDIT

· Light and easy to move

3LPE Coated pipe is light in weight. It only accounts 1/8 weight of steel pipe. Because of its characteristics of softness and corrosion resistant properties, it is easy to move, and easy to bend. Welding process of this pipe coating is convenient and fast.