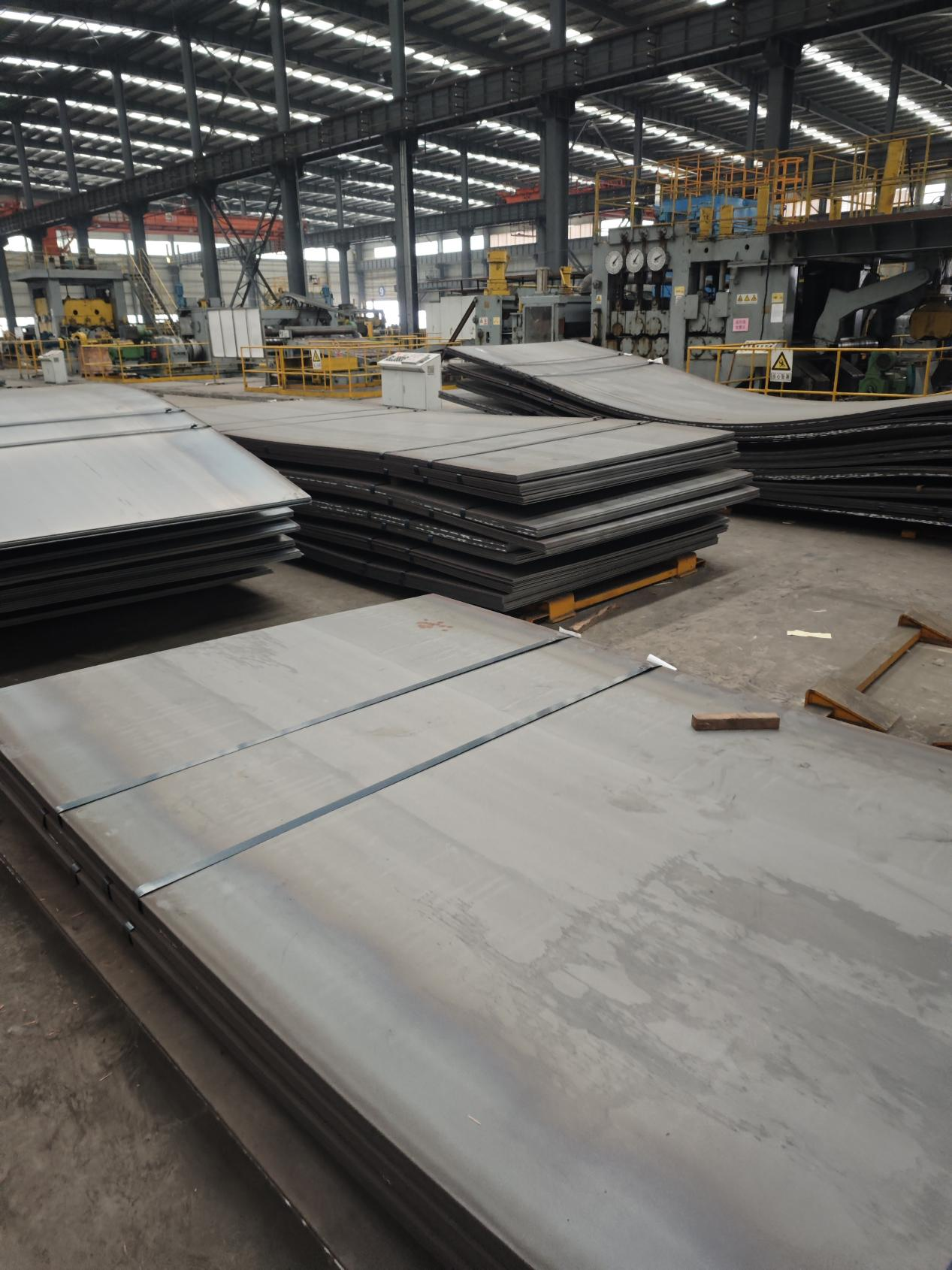

Hot rolled plate is a steel plate produced by a high temperature rolling process. Specifically, the steel billet is heated to a certain temperature to soften it, and then pressure is applied through a rolling mill to reduce its thickness and increase its width to obtain the desired plate. The whole process is carried out at high temperature, so it is called hot rolling.

Heating: The steel slab is heated to above the recrystallization temperature to give it good plasticity.

Rough rolling: The heated steel slab is passed through the rough rolling mill to significantly reduce its thickness.

Finishing rolling: The steel plate is subjected to the final thickness and size adjustment on the finishing mill.

Cooling: The rolled steel plate is cooled and subjected to necessary surface treatment.

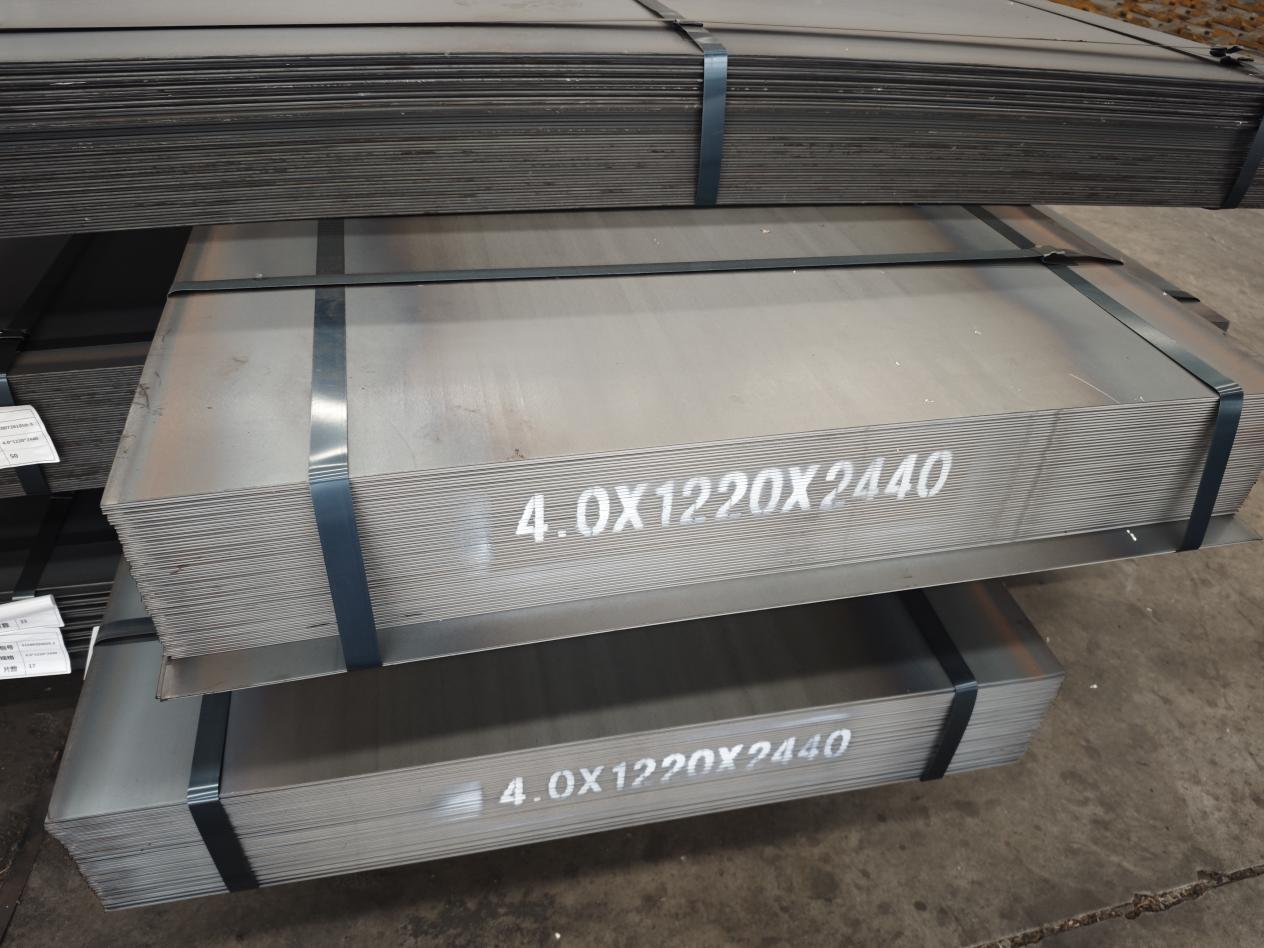

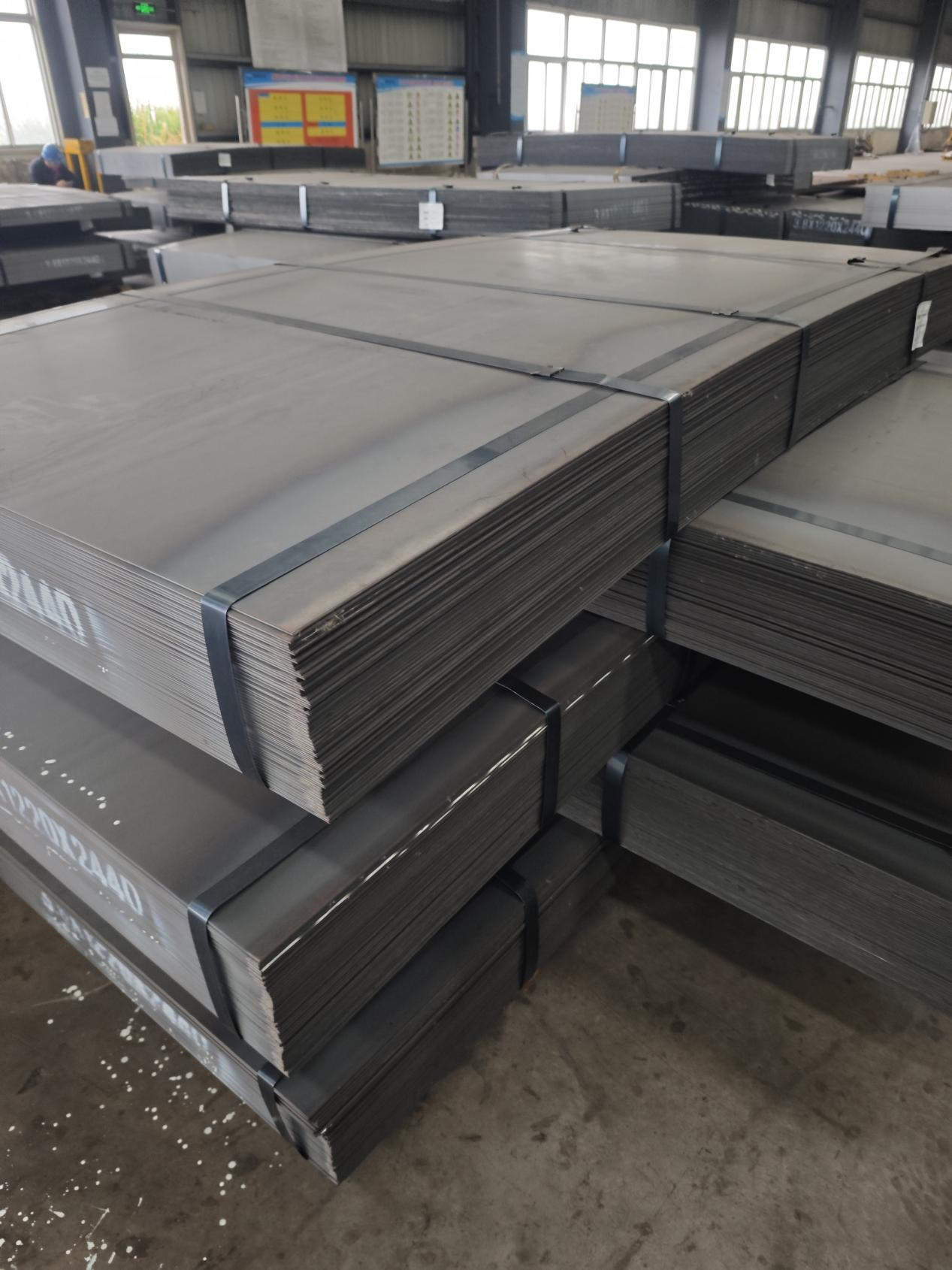

Width:600-2500mm

Thickness:2.5-25.4mm

Length: The length of hot-rolled plates can be customized according to customer requirements, generally ranging from a few meters to tens of meters.

Grade:Q235,Q355,SS400,SS490,S235JR,S275JR

Standard:BS EN10025, GB/T14164

High strength and good toughness: Plastic deformation at high temperature refines the grain structure of steel, thereby improving the strength and toughness of steel.

Low cost: Compared with cold-rolled plates, the production process of hot-rolled plates is relatively simple and the cost is low.

Various sizes and specifications: The thickness range of hot-rolled plates is wide, which can meet the needs of different users.

Good processing performance: Hot-rolled plates have good weldability, cutting performance and forming performance.

CREDIT

Hot-rolled plates have a wide range of applications, mainly used for:

Construction industry: raw materials for the production of H-shaped steel, channel steel, angle steel and other profiles.

Machinery manufacturing industry: base plates, frames, etc. of large machinery and equipment.

Automobile industry: automobile bodies, chassis and other parts.

Shipbuilding industry: hull plates.

Bridge construction: bridge steel plates.

Pressure vessels: storage tanks, boilers, etc.

CREDIT